- Home

- Knowledge library

- Treatments for the control of pest and mites in grain stores

Treatments for the control of pest and mites in grain stores

It is important to monitor for pests and mites in grain stores, and to investigate sources of infestation. In addition to reviewing grain condition and practices, consider the need for pesticide treatment – either with residual insecticides, fumigants or physical desiccants.

How the grain store environment affects pest levels

Monitoring insect and mite populations in grain stores

When to use pesticide treatments in grain stores

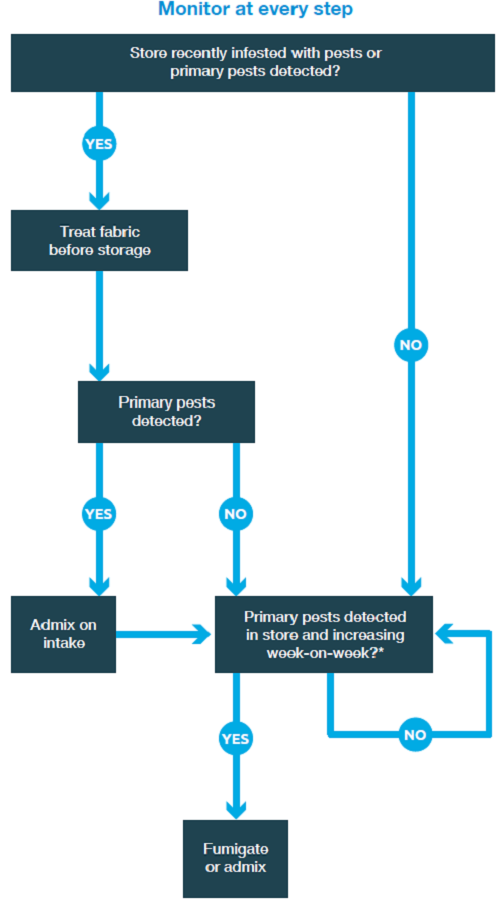

It is important to monitor at every step of the grain storage process – from before intake to final dispatch.

Treatment of store fabric

Before grain enters the store, if pests are persistent or widespread, consider applying an approved pesticide to the fabric of the building at the manufacturer’s recommended rate.

The intended use and market of the grain may determine the products that can be applied. Chemical treatment to prevent fungal growth can only be used on grain for animal feed.

Ensure that the correct rate is applied with serviced and calibrated application equipment. This will also minimise the risk of exceeding maximum residue limits and pesticide resistance. Details of all treatments should be documented.

The efficacy of any treatment can be monitored by checking and replacing insect/mite traps two days after treatment.

Residual insecticides/admixtures

Application of a residual insecticide (by trained personnel):

- Provides protection over a prolonged period, dependent on the type of surface and the temperature

- May take time to control an existing infestation

- May take a relatively long time to achieve control at lower temperatures (depending on the active ingredient)

If a residual pesticide treatment is used, it must have approved usage for admixture to the grain and be applied at the manufacturer’s recommended rate. Currently, only organophosphorus (OP) compounds are approved for admixture to grain. In cereals, mites can be discouraged by accurate application to the bulk of a liquid OP at recommended rates. Dust formulations are no longer available. Treatment of infestations is more difficult, as they are not particularly susceptible to OPs.

Fumigants

- No lasting activity but penetrate and disinfect static bulks

- Control all stages of infestation in one treatment, if correctly applied

Diatomaceous earth (DE)

- A physical control (siliceous dust) that desiccates insects and mites (limiting population growth)

- Not accepted by some supply chains due to health and safety concerns (dust) and the inability to remove it from the grain, which can affect machinery

- If the entire bulk is treated, DE may limit grain flow. As a result, it can only be incorporated at effective application rates to the grain surface

- Only gives longer-term control when combined with an effective drying and cooling regime

- To prevent mites occurring at the surface of grain, rake DE into the top 0.3 m at 200 g/m2 (1 g/kg). To deal with surface infestations, treat with 600 g/m2 (3 g/kg)

- Control of the least susceptible pest, grain weevils, could take several weeks

Insecticides and resistance

Information on plant protection products approved for UK use (structural and grain treatments) is available from the Chemicals Regulation Division (CRD) website.

Chemicals Regulation Division (CRD) website

Some pest insects and mites have developed resistance to some currently approved pesticides. Resistance management includes ensuring correct application at the manufacturer’s recommended rate and consideration of the use of a product containing an active substance with a different mode of action (MOA) to that used previously. For further information, visit the Insecticide Resistance Action Group (IRAG) web page.

Insecticide Resistance Action Group (IRAG) web page

Personal protective equipment (PPE)

When using chemical treatments, take appropriate safety measures, including the use of adequate personal protective equipment (PPE). PPE is also essential when stores are cleaned, loaded and unloaded.

Fera.JPG) Crown Copyright

Crown Copyright

*In store, cool grain rapidly.