- Home

- Knowledge library

- Soil compaction from machinery

Soil compaction from machinery

Compaction is seen where there has been traffic on wet soils. All soil textures can show damage from compaction. The greater the weight of the vehicle and tyre pressure, the deeper the potential compaction.

Introduction

Poor soil structure and compacted layers usually result from overloading, cultivating or lifting wet soils that are not strong enough to hold the weight of machinery.

In medium and clay soils, this results in deformation through smearing and puddling.

In sandy and light silty soils, compression increases soil density.

Generally, soils that are low in soil organic matter are more susceptible to soil compaction and structural deterioration.

Quick in-hand checks

Crumb and granular structures:

- Crumble in your hands

- Are associated with abundant fine roots

- Are normally dark brown in colour

- Have abundant pores

- Smell earthy

Compacted soil is:

- Firm or hard to break up by hand

- Normally paler in colour

- Has few roots

- Is dominated by horizontal cracks/fissures and platy structures

- Has few visible pores

For a simple step-by-step guide to assessing your soil structure, check out our How to assess soil structure (VESS) guide.

Symptoms

Signs of compaction include:

- Very large angular or platy aggregates and/or a very dense compacted layer (pan)

- A web of roots growing horizontally with only a few penetrating to any depth, suggesting hard-to-penetrate layers or blocks of soil

- Poor drainage

- Rapid changes in water content within the soil, with wet and dry zones adjacent

- A saturated layer that may be duller in colour and, if associated with incorporated residues, may smell of bad eggs

- When a block of soil has been extracted for assessment, soil water may trickle into the pit from a compacted layer above

Water seepage from above compacted soil layer

Solutions

To understand the extent and nature of the compaction, first dig some holes to look at the soil structure. Then follow our simple How to assess soil structure (VESS) guide.

Nature-based solutions

Some soils have the natural capability to repair or self-structure. For example, clay soils can produce effective cracks in dry or frosty conditions.

All soils can be improved naturally by:

- Planting crops with different rooting depths to break up the compacted layer and improve soil structure, e.g. using a cover crop or multi-species sward

- On arable land, diversify crop rotations, especially the inclusion of no-till periods (e.g. ley-arable rotations)

Machinery-based solutions

- Improve drainage

- On grassland:

- A sward slitter or aerator can remove compaction <10 cm depth

- A sward lifter/top-soiler can remove compaction in sub-surface layers (over 10 cm) and help with restructuring

- On arable land, use targeted cultivations under the right soil conditions

After the cultivator has passed, dig a hole to check it is having the desired effect (rather than causing damage).

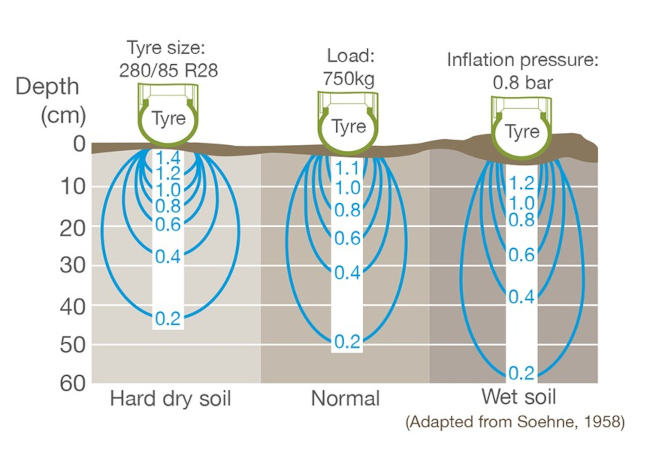

The effect of increasing soil moisture on the depth and severity of soil compaction

How to prevent compaction from machinery

Good soil structure is best maintained by avoiding soil compaction in the first place.

Where possible:

- Maintain field drains and ditches to ensure existing draining systems remain effective − see the AHDB field drainage guide for more information

- Ensure good ground cover

- Keep off fields for 48 hours following heavy rainfall as wet soil is extremely vulnerable to compaction

- Avoid driving on soils where any layer(s) in the top 40 cm are above their plastic limit

- Avoid overusing entrances; use a separate exit

- Consider established wheelings or reduced traffic systems

- Reduce the pressure to the ground using larger tyres and lower inflation pressures

- Reduce machine size and total axle loads; wheel loads greater than 3.5 tonnes can cause serious, permanent, deep-seated compaction, even with large low-pressure tyres

- For slurry-based systems, consider separation to ensure nutrients can be spread with less weight being carried

Machine size

Consider the 8–8 rule:

Under wet conditions, the depth of compaction beyond 30 cm depth increases by 8 cm for each 1 tonne increase in wheel load (above 1 tonne) and by 8 cm for each doubling of the tyre inflation pressure (above 1 bar).

Remember:

- The greater the weight of the vehicle, the deeper the potential compaction

- The greater the tyre pressure, the greater the degree of compaction in the topsoil and upper subsoil

- If the soil is wet, the risk of compaction moves deeper into the soil profile

Useful links

Read our quick and easy guide on how to assess soil structure

Read about the impact of soil compaction on grassland

Find out how to easily assess soil moisture content ahead of cultivation

Find out more about machinery to loosen arable soils

Find out more about machinery for removing compaction on grassland soils

See visual case studies of soil compaction by machinery in the Environment Agency think soils manual