- Home

- Knowledge library

- The use of machinery to loosen soils for arable crops

The use of machinery to loosen soils for arable crops

Find out how to assess the need for soil loosening (including subsoiling) and how to get the best out of machinery to help restructure soils.

How to assess the need for soil loosening

Dig through moist subsoil in a crop to identify potential issues. Compaction signs include:

- Obvious differences in soil moisture and root growth at any common depth

- Absence of visible porosity, including fissures and root channels (which should mainly extend vertically to allow free passage of water, air and roots)

Reassess any area with signs of compaction after harvest, as roots can repair damage.

Where damage remains, take remedial action.

How machinery affects soil loosening

The type of machinery and the way it is used can affect soil loosening in the following ways:

- Forward-inclined tines at the surface can reduce disruption

- Curved or sideways-inclined tines enable the leg to pass through cleanly, especially in shallower situations

- Shallow leading tines/pre-cultivations reduce lifting requirements for following deeper tines

- Leading discs (aligned to the tines) can reduce surface disturbance and cut surface residues and roots, allowing these to pass by the tines most efficiently

- Rear roller action determines the field finish and consolidates the soil profile to working depth; this maintains surface stability and minimises excessive loss of organic matter (through oxidation) by closing the soil surface in a controlled manner

- Speed of operation – faster speeds imply reduced lift height is needed

Note: Loosening with low surface disturbance at shallow depths (between 15 cm and 30 cm) can usually be achieved by a grassland-type sward lifter operation.

Implement geometry

Fundamental principles of geometry govern the interaction of soil and metal.

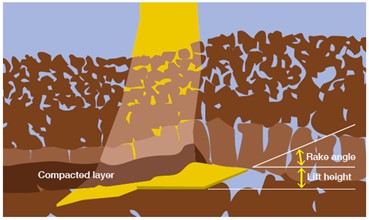

The interaction between rake angle and wing lift height determines the degree of vertical fissure creation, surface disruption and heave.

Rake angle

Rake angle is the angle from the ground to the soil-engaging part of a tool. It largely determines the action on the soil.

Rake angles can vary with implement type:

- Discs and rollers, plus wheels, have high rake angles and can cut or compress the soil and any residues on the surface

- Tines have high-to-low rake angles

High rake angles:

- Work most effectively in dry to friable conditions

- Can cut or compress and disintegrate clods and minimise surface lifting and disturbance

- Can smear and compact the soil if compressive action is used in plastic conditions

Intermediate rake angles:

- Can sort and partially disintegrate clods, pushing them against the bulk strength of the soil ahead

- Can sort small aggregates or clods into larger gaps, creating an ordered tilth with few large open spaces

Low rake angles:

- Are suited to dry, friable or slightly damp conditions

- Predominantly lift and loosen, raising the soil upwards, putting it into tension where brittle failure or breakages create fissures or cracks

- Minimise surface disturbance and heave, provided lift height is adequate for fissure creation

- Have a low risk of smearing

- Assist drainage and can support loads from above with less risk of re-compaction

- Are most effective when speed is not too high; aggressive lifting (lifting at high speed or with intermediate-to-low rake angles) can cause high disturbance and leave a profile that is more prone to re-compaction or slumping

Wing lift height

The vertical lift height of tine wings influences the degree of soil loosening.

Where more soil lift is required for fissuring, aim to increase the length of the lifting parts (for more wing lift height) rather than their rake angle.

Do not reduce lift too much to achieve minimal surface disturbance. This can make restructuring ineffective.

High vertical lift:

- Completely rearranges structure and the natural column strength is lost

- Examples include conventional, deep subsoilers with high wing lift operated at shallow depths

Low vertical lift:

- Does not create vertical fissures through compacted layers

- Examples include low disturbance looseners operated at subsoiling depth

Effective soil loosening

When setting up machinery:

- Set loosening tines to achieve vertical fissures through the compacted layers, with minimal disturbance of the profile

- Avoid using deep loosening wings with high lift at shallow depths; this can result in excessive soil movement and destabilisation of the profile

- Avoid aggressive loosening actions that cause a loss of natural structure and aggregation at depth

- Set the wing leading edge below the depth of compaction by 2–3 cm and allow for local field variability

- Consider fuel use – an increase in loosening depth of 5 cm can double the fuel

- Doubling loosening depth can quadruple the draft loads

- Use reduced-disturbance actions to reduce mixing of weed seeds through the soil profile

Prior to operation:

- Ensure appropriate soil moisture levels at and above the loosening depth to ‘stretch’ soils and create vertical fissures

Follow best practice and:

- Only loosen the affected area (for example, turning headlands or specific soil textures)

- Do not loosen deeper than needed, and consider the actions of roots

- Loosen through a cover or catch crop if root growth appears restricted

- Where greater variations occur (for example, deeply compacted headlands), adjust the machine to the areas managed

As you go:

- Assess the impact of soil loosening on compacted layers (i.e. look for vertical fissures, not a compressed channel)

- Adjust settings, if required

Post-loosening:

Loosened profiles can rapidly reconsolidate, losing any beneficial effects. To stabilise loosened soil, establish a crop as soon as possible.