- Home

- Knowledge library

- Fan ventilation in pig buildings (extraction)

Fan ventilation in pig buildings (extraction)

From ridge mounted fans with side inlets through to high speed jet systems, this information looks at different fan extraction methods for pig building ventilation.

In most mechanical ventilation systems used for livestock, the most common component is the propeller fan. These are characterised by a ‘paddle’ impeller, which can move large amounts of air at relatively low back pressures.

Most applications use single-phase fans of up to 630 mm in diameter. Propeller fans are comparatively cheap, easy to install and reliable.

Some modern types of propeller fan use an impeller with an aerofoil cross-section instead of a paddle blade and are capable of operating at higher pressures; these are referred to as axial flow fans.

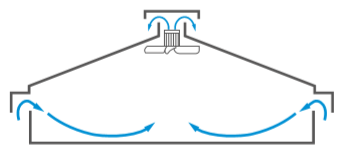

Ridge extraction with side inlets

This is the most commonly used system for larger pig buildings.

They are ridge-mounted fans with sidewall inlets, fitted with either manually or automatically adjusted shutters (see Figure 1 below).

With the introduction of cost-effective advanced control systems, the latter is now the norm for a new build. It is also favoured for its ability to eject ammonia, odour and dust upward into the atmosphere for better dispersal.

You should not duct outside air from ground level. It is better to invert the baffles to draw air from the eaves because differences in wind pressure are lower.

Figure 1. A ridge extraction system

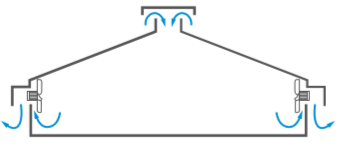

Side extraction with ridge inlet

This is the opposite of the ridge extraction system, however, it suffers from the same inherent problems of susceptibility to wind effects.

These installations benefit from the use of wind cowls, which push air to the level of the eaves rather than to the floor (see Figure 2).

Incoming air distribution also benefits from automatic louvre control. This system has the advantage of wall-mounted fans that are easily accessible for maintenance purposes.

Figure 2. A side extraction system

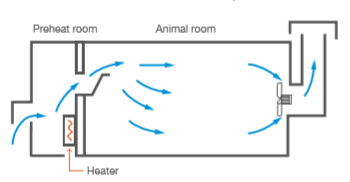

Crossflow

Many smaller, low profile pig buildings use crossflow ventilation, and it is a common system for heated flatdecks.

As the name suggests, air flows across the building, between inlets and outlets at opposite sides of the structure (see Figure 3).

Great care has to be taken to avoid cold draughts from the inlets, either by preheating or by diffusing the incoming air.

Preheating in an entrance lobby is common, but this can lead to reversed air flows caused by convection currents set up by the pre-heated air.

Crossflow ventilation systems are inherently susceptible to wind, but this can also be solved by placing the inlets and outlets on the same wall.

Figure 3. A crossflow system

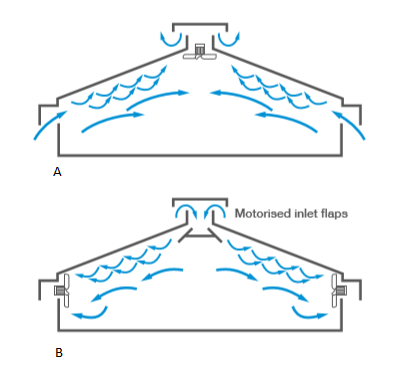

High-speed jet

The high-speed jet system is an adaptation of the ridge/side inlets/outlets system (see Figure 4).

It has modifications to keep the air inlet velocity high at all ventilation volumes. Therefore, it has the advantage that internal air patterns can be kept consistent in all conditions and it can prevent low-speed cold air dropping just beyond the inlet.

The recommended commissioning inlet air speed is around 4–5m/s. The system can either have eave-level or ridge inlets and has the provision to modulate its apertures according to the amount of air handled by the fans. Thus, as the controller decreases the ventilation rates as ambient temperature falls, the inlet apertures close slowly so that air maintains its speed.

By ‘squirting’ along the roof section, the air clings to the inner skin of the roof by the phenomenon known as the Coanda effect. There must be no obstructions, such as battens, structural beams or lights.

The air is entrained at high level and mixes thoroughly with the internal warm air before getting near to the stock. This mechanism maintains defined air patterns, irrespective of outside conditions.

The inlets are moved by electrically-driven rams or via a steel cable and pulley arrangement. The control of the fans has to be interlocked with the control of the inlets, so the operation of the two systems is synchronised.

This high-speed jet system is more windproof than the other systems which have been mentioned above.

Sequential full-speed operation of the fans is most suitable here because they have to operate against their design back pressure in all conditions to overcome the resistance of the inlet.

Figure 4. High speed jet systems

A. High speed jet side inlet

B. High speed jet outlet

Topics:

Sectors:

Tags: