- Home

- Knowledge library

- Environmental and management techniques to reduce ammonia emissions for housed cattle

Environmental and management techniques to reduce ammonia emissions for housed cattle

The rate of ammonia volatilisation from floors is influenced by ambient temperature and air exchange rate. Controlling these factors will reduce ammonia emissions.

Controlled environment dairy housing

Cross-ventilation sheds

While not commonplace in the UK or across Europe, cross-ventilation sheds are more common in the US. Insulated buildings can provide a cooler environment in warm weather. The heat from animals needs to be removed by good ventilation to limit temperature rises and the risk of heat stress. Conversely, increasing this air exchange to remove heat will increase ammonia volatilisation.

Traditional slatted sheds

In cattle buildings with traditional slats (either non-sloping, 1% sloping or grooved), optimal shed climatisation with roof insulation and/or automatically controlled natural ventilation can achieve a moderate emission reduction (20%) due to the decreased temperature (especially in summer) and reduced air velocities (Braam, Ketelaars and Smits 1997; Bram and others, 1997; Smits, 1998; Monteny, 2000). However, consideration must be given to providing an optimal environment for the cow.

Air scrubbers

Chemical or acid air scrubbers, while effective in decreasing NH3 emissions from force-ventilated pig housing, cannot usually be installed in cattle housing which is mostly naturally ventilated.

Similar to the ‘slats with flaps’ concept, baffles have been used to reduce the airflow across the surface of an underfloor slurry store.

Air scrubbers can be incorporated with forced ventilation, but this requires a large capital investment as most cattle buildings are naturally ventilated. There could also be a public perception issue.

Slurry cooling

The most significant source of ammonia in livestock production is the breakdown of urea, which is excreted in urine by the enzyme urease into ammonia and carbon dioxide. In addition to the concentration of urea in urine and the rate of air exchange, pH and temperature of the slurry are factors affecting volatilisation rates.

Installation

Cooling equipment can be installed in floors of cattle buildings or in slurry stores to reduce the temperature, and therefore reduce ammonia emissions.

Most frequently, a cooling circuit is installed in or on the floor of under-slat or other relatively long-term slurry storage. It can also be installed in the floor of slurry channels where movement is likely to disturb pipes fixed to the floor.

18 mm Low Density Polyethylene (LDPE) pipes are cast into or fixed to the floor at 350-400 mm spacings with pipes plumbed in parallel to reduce differential cooling.

Glycol or other forms of antifreeze can be added to the contents of the closed cooling loop to cool slurry to temperatures to 0°C or lower. Extreme cooling has been found to reduce the efficiency of the heat pump, and best available technique (BAT) recommendations for pig housing are designed to cool the slurry to around 5°C.

Using water

Cooling water can be passed through a floating heat exchanger, where arrays of plastic or metal fins are used. The fins are filled with cold water and placed in the pit to float over the slurry.

Most data on slurry cooling comes from work done with pigs. Testing on pig fattening units in Denmark showed that ammonia emissions were reduced by 10% for every 10W/m2 cooling achieved. Financial viability of these techniques is dependent on recycling the heat recovered from the slurry.

Reduced pH of slurry

Lowering the pH of slurry stored under a slatted floor to 4.5 by adding nitric acid resulted in a 37% reduction in ammonia emissions from cow slurry (Bleijenberg et al. (1995)). However, the use of nitric acid has health and safety implications and nitrogen concentrations in slurry are an additional risk to the environment.

Adding sulphuric acid to reduce pH is well documented in pig enterprises. Reducing the pH of pig slurry to 5 converts NH3 into NH4, which will not volatilise. This technique has recorded a reduction of 50–70% in ammonia emissions.

This specialist process, widely used in Denmark, uses technical equipment for pH reduction and should only be approached with expert advice. This is a viable technique but requires significant capital investment and increases risks from poisonous gasses and foaming.

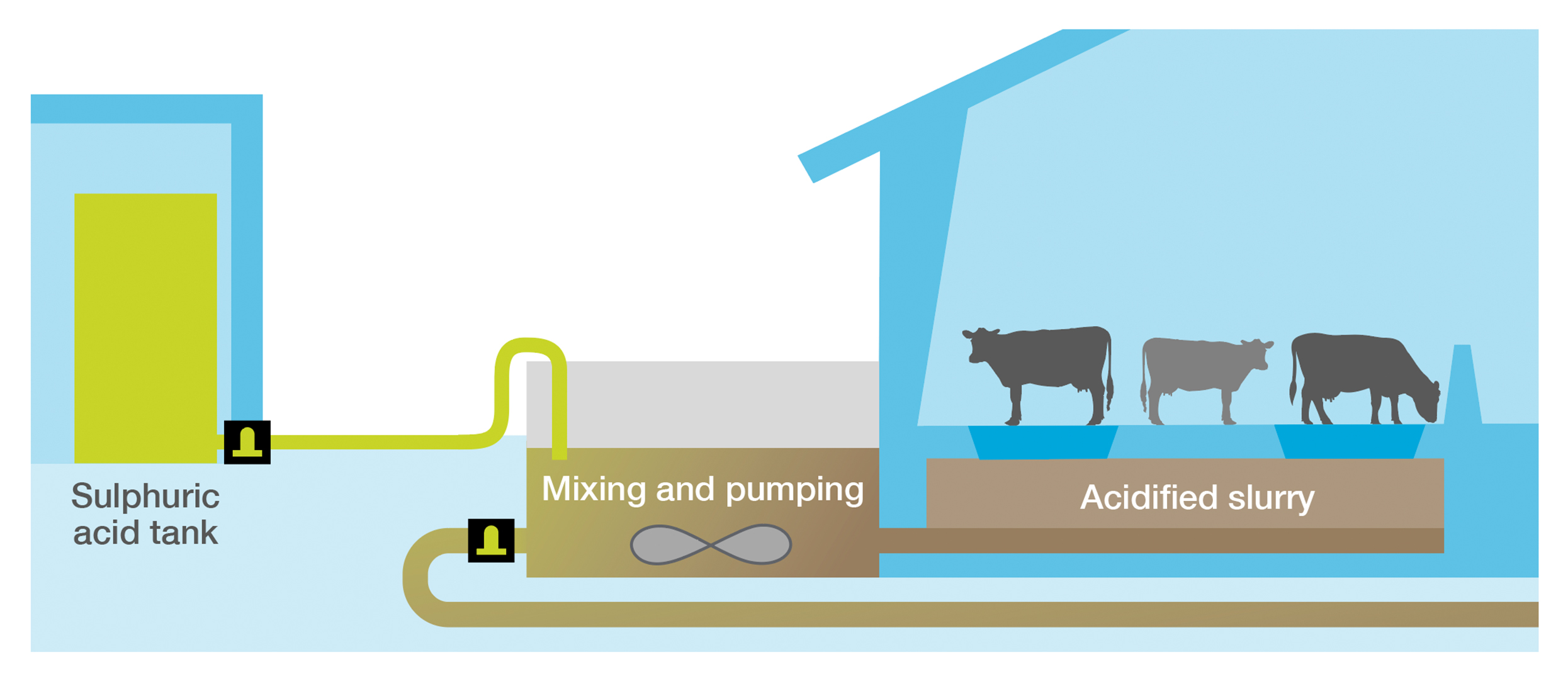

Slurry is pumped into a tank of sulphuric acid (see diagram below), lowering the pH from typically around 7 to 5.5. The process is controlled by pH sensors.

When the desired pH is reached, slurry is automatically pumped back into the store and a smaller amount of freshly acidified slurry is pumped into the storage tank. This process is usually repeated once a day for each cattle shed.

Acidified slurry is easier to pump and less vulnerable to loss of nitrogen as ammonia when spreading, reducing the effect of the application method.

In-tank and in-field acidification can reduce emissions when the slurry is spread, but it is still a specialist operation.

Reduced floor area

Restricting the floor area accessible to the cow reduces the surface area contaminated with slurry and lowers ammonia emissions. However, this is contrary to best practice advice for optimal animal welfare.

Ammonia emissions were reduced by approximately 10% when the fouled floor area per cow was reduced from 3.5 to 2.5 m2 in an adapted design for a dairy cow house with cubicles (Metz et al., 1995).

Optimising animal welfare conditions tends to lead to an increase of fouled walking area per animal, increased ventilation, possibly cooler temperatures and an overall increase in emissions.

Combined scraping and flushing system

Several systems have been trialled involving the regular removal of the slurry from the floor to a covered store outside of the building. These involve flushing with water, acid, diluted or mechanically separated slurry, or scraping with or without water sprinklers.

In general, these systems have proven to be ineffective or too problematic to maintain. The use of smooth and/or sloping floors to assist in scraping or flushing contributes to cows slipping which is very detrimental to animal health and welfare.

The table below shows ammonia emissions of different cattle housing systems. The ‘cubicle house’ type system is used as the reference system from which the other housing systems in the table are compared.

|

Housing type |

Reduction (%) |

NH3 emissiona (kg/cow place/year) |

|

Cubicle house |

n.a. |

12.0b |

|

Grooved floor |

25–46 |

9.0 |

|

Optimal barn climatisation with roof insulation |

20 |

9.6 |

|

Chemical air scrubbers (forced ventilation systems only) |

70–90 |

1.2 |

|

Grazing 12h/24h |

10 |

10.8c |

|

Grazing 18h/24h |

30 |

8.4c |

|

Grazing 22h/24h |

50 |

6.0c |

Source: Guidance document on preventing and abating ammonia

Abbreviation: n.a. = not applicable.

a Emissions with full-time housing of the animals.

b Based on a walking area of 4–4.5 m2 per cow and permanent housing.

c These numbers hold for season-long grazing (assumed about 200 days). They show the relative reduction of annual emissions as compared with the reference system with no grazing. Grazing for part of the days requires that barn surfaces are always kept clean.

Loose housing

Housing cows in an open yard on deep straw can result in up to a 25% reduction in ammonia emissions per cow. This is dependent on the bedded area and the amount of hard surface loafing area provided per cow. Increased bedding quantity and frequency also lower emissions.

However, this must be offset by the increased methane production from FYM compared with slurry. Groenestein & Reitsma (1993) found methane emissions of approximately 1 kg per day per cow for these systems. This is substantially higher than average methane emissions from slurry based dairy cow housing systems which equate to 0.15–0.37 kg per day per cow (Crutzen et al., 1986; Van Der Hoek, 1984) There are also more opportunities for ammonia abatement measures in cubicle housed systems.

Bedding material in animal housing can affect NH3 emission. The physical characteristics (urine absorbance capacity, bulk density) of bedding materials are of more importance than their chemical characteristics (pH, cation exchange capacity, carbon to nitrogen ratio) in determining NH3 emissions from cattle shed floors (Misselbrook and Powell, 2005; Powell, Misselbrook and Casler, 2008; Gillespy and others, 2009). However, further assessment is needed on the effect of bedding on emissions for specific systems while considering the whole manure management path.

Trials have been conducted with deep bedded woodchip pads, up to one metre deep, with heated air forced up from beneath. The wood chip allows good drainage of the urine and the warm air dries the material. The surface should be ‘cultivated’ daily to incorporate the faeces as it dries.

Stocking rates of around 15m2 per animal are important to avoid over-fouling, which adds to the capital cost per cow.