- Home

- Knowledge library

- Cultivator drilling on arable land

Cultivator drilling on arable land

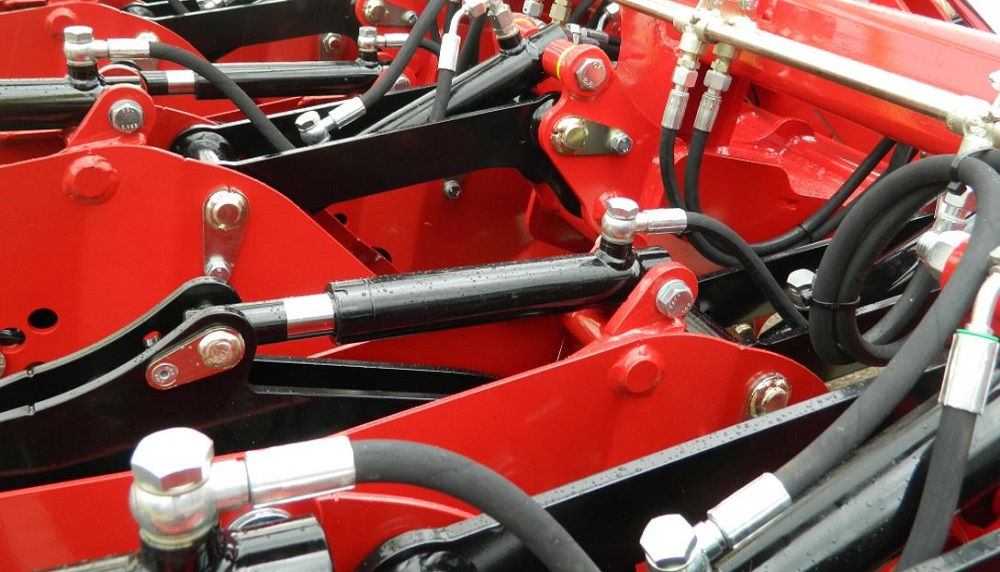

Direct drilling with a cultivator-type drill uses some form of cultivation (e.g. to loosen topsoil before seed placement) followed by rollers to firm the soil.

Overview

Combining cultivation and drilling into one operation is another way of minimising passes and, in effect, directly drilling into the previous crop stubble.

Pros and cons of cultivator drilling

Pros:

- A single-pass system with flexibility for some cultivation

- Allows appropriate mix of tillage and drilling on soils needing both

- Low cost of operation (other than capital outlay)

- Reasonable/high output

- Low disturbance for weed management and, as needed, some structuring

- Over time, soil structure and biological activity improves

Cons:

- Ideally, needs tilth to be present for the following crop

- Specialist kit is required, although it can be based around a cultivator drill

- Residue manager (row sweep) options can be required to give clear drilling zones

- Allow for restructuring, if needed, even as a separate pass

- Generally reliant on rotations and/or chemicals for weed control

Machinery considerations

Tine-based drills can benefit from leading discs. These will cut residues and reduce disturbance.

The detailed design of the opener, including its rake or lift angle, is important. This will determine soil movement and closing requirements.

Disc-based (no-till) drills

Such drills can cope with high levels of surface residue. However, the design should avoid ‘hair-pinning’ high levels of residue into the seeding zone.

Factors to consider with disc-based drills:

- They have a greater risk of smear, especially in wetter conditions

- The total weight required for disc penetration increases with disc size

- Discs, which disturb and throw less soil than tines, need less remedial action to produce a level, consistent surface

- Angled disc slots are closed by vertical pressure and vice versa

The opener design is critical. This includes the tilt angle of the disc, the drop tube position (relative to a single disc) and whether twin-disc or triple-disc openers are used.

Pros:

- A single-pass system that requires adequate structure (tilth and subsurface)

- Reduced overall costs (fuel and machinery)

- No other operations – simple to manage in suitable conditions

- Successfully used by some farmers on appropriate soils

- Opportunity to increase area of autumn-sown crops

- High work rates and area capability

- Drilling phased to take advantage of favourable weather conditions

- Stones not brought to the surface

- No compaction below plough furrow

- Reduced erosion, run-off and loss of particulate P

- Better retention of soil moisture in dry areas

Cons:

- Usually needs a specialist, high-cost kit

- Can require careful residue management when drilling (row sweeps)

- All tilth needed for the following crop needs to be naturally made

- Needs good weather and, often, patience to create good tilth; can impose high demand on management where soils are variable

- Drill slot closure can be problematic in certain soils and moisture levels

- High levels of surface residues imply a disc is needed somewhere

- Increased grass weed control problems and heavy reliance on rotations and/or chemicals for weed control

- Crop establishment problems during very wet or very dry spells

- Increased risk of topsoil compaction

- Problems with eradicating residual plough pans

- Risks of increased nitrous oxide (N2O) emissions and leaching of dissolved reactive P

- Unsuited to incorporation of solid animal manures

- Increased risk of fusarium infection and mycotoxins, e.g. deoxynivalenol (DON)