- Home

- Knowledge library

- Dairy cow cubicle housing design to control environmental mastitis in lactation

Dairy cow cubicle housing design to control environmental mastitis in lactation

Keeping cow bedding materials and other surfaces cows encounter clean and dry is essential, to reduce the risk of environmental mastitis infections. Cow comfort and housing design are also key areas of consideration.

Back to: Environmental mastitis – the housed dairy cow

Cubicle housing for lactating cows

Infection with bacteria from the environment can happen at any time between and during milkings. To reduce the risk from environmental sources of mastitis, it is important to keep levels of bacteria on the teats and near teat ends low. In housing, keep bedding and other surfaces with which cows come into contact clean and dry. This will help to reduce the risk of environmental infection.

Cow comfort is a key factor in reducing environmental risks for mastitis. Housing designed with the cow in mind is important. Even in well-designed housing, providing enough clean and dry bedding with regular maintenance is essential.

Well-managed cubicles give a lower incidence of mastitis infections in lactation compared with loose yard systems, in general. To minimise the risk of mastitis infections, aim to:

- Minimise cows lying out in the passageways

- Reduce manure soiling of the cubicle beds

- Minimise the risk of teat and udder injury

- Pay close attention to cubicle bed management

Cubicle size and design

Cubicles must be appropriate to the size of the cows in the herd and designed so that 90% of cows will lie in them correctly at all times:

- The minimum cubicle size must be greater than 2.36 m long x 1.15 m wide (7'9" x 3'9") and should be more than 43 m long x 1.22 m wide (8' x 4') for Holstein-Friesian cows

- There should be a slope on the cubicles, front to back, of 1 in 20 to ensure good drainage

- There should be an adjustable brisket board (or cow pillow) in the cubicles at a distance of approximately 75% of the cubicle length, to ensure that at least 90% of the cow’s dung goes into the passageway

- Neck rails should be adjustable. The diagonal distance from rear kerb to neck rail should be more than 200 cm (216 cm for Holsteins)

Cubicle partitions should not have a bottom rail lower than 0.4 m and could have flexible partitions, as seen in the image below.

Image courtesy and copyright of James Breen BVSc PhD DCHP MRCVS.

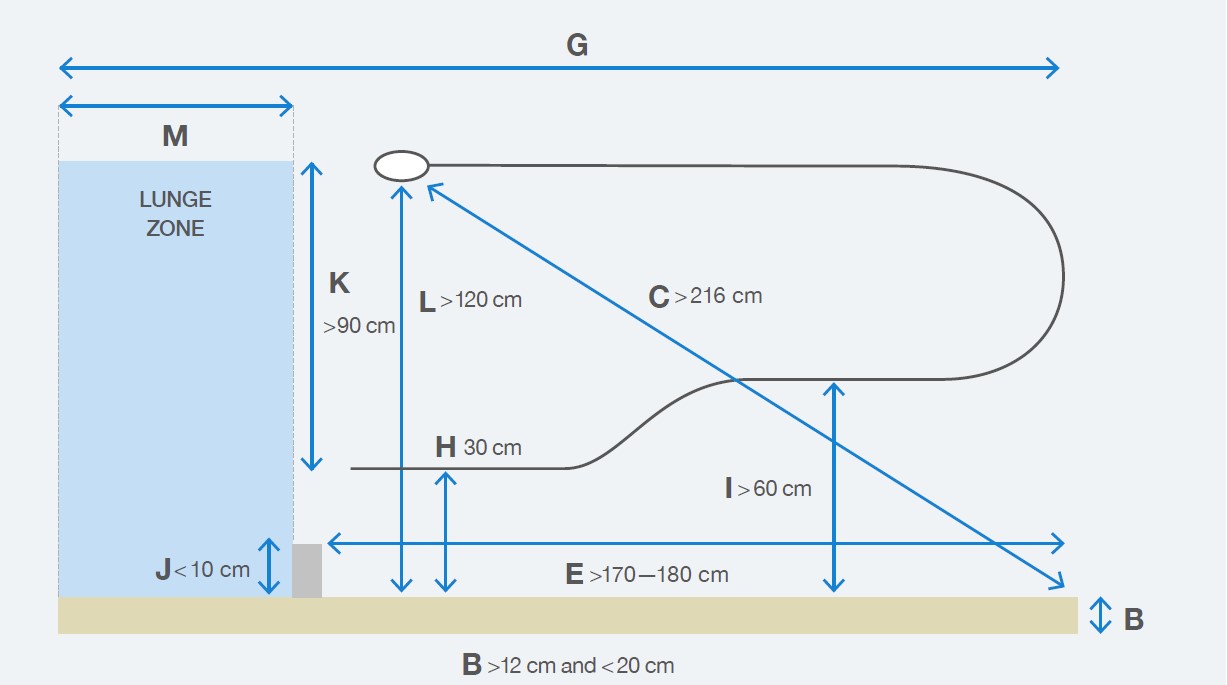

The graphic below shows recommended cubicle dimensions for Holstein-Friesian cows over 600 kg:

- B – Cubicle rear curb height

- C – Diagonal neck rail to rear

- E – Brisket to rear of cubicle

- G – Total length

- H – Height of lowest rail at head end

- I – Height of lowest rail at rear

- J – Brisket board's height

- K – Side lunge

- L – Neck rail height

- M – Lunge zone

Source: K.A Leach and H.R Whay 2009; The welfare quality lameness control programme for Dairy Cattle – Welfare quality report No. 14, p26 www.welfarequality.net/media/1122/wqr14.pdf

Stocking rate

The stocking rate for lactating cows housed in cubicles can be an underlying issue for some herds. It may be difficult to control the risk of environmental infection from high stocking rates even with gold standard milking parlour routines.

High stocking rates can be a particular risk in low cell count herds where the impact of environmental infections can be dramatic. Cows are herd animals and prefer to synchronise their behaviour by lying down at the same time.

In early lactation and heifer groups, stocking rate at 80% occupancy is recommended. This occupancy level gives more choice of lying spaces as well as reducing competition for resources and bullying behaviour.

It is important to ensure:

- 90% of cows lie correctly in cubicles at all times

- There are at least as many cubicles as cows (Red Tractor)

- Ideally, there are 5% more cubicles than cows for each group (e.g. a 100-cow group should have 105 cubicles)

- New, clean bedding material is applied at least once daily for organic bedding. Twice-daily application of new, clean bedding should be considered if problems persist

- Clean bedding material is applied at least once every other day for inorganic bedding materials such as sand

- Dung, soiling and wet bedding is removed at least twice daily from cubicle beds for lactating cows

Management of cubicle beds

In cubicles, using enough bedding material will keep surface conditions dry and will make the bed soft and cushioned enough for cow comfort.

It is especially important that clean bedding is placed where the cow’s udder will be when she lies down. Cows move around in their bed when lying down, much as we do. Even if there are mattresses in a cubicle, bedding is always needed to absorb the moisture (urine and milk), reduce the risk of mastitis, make it comfortable and help reduce friction sores.

Milk leaking onto beds from high-yielding cows is a potential source of nutrition for bacteria already in the bedding and may also contain additional bacteria that will cause further contamination.

You can easily check whether a bed is comfortable and dry enough for the cows by performing the following tests:

Wet knee test

Kneel in the stall for 10–30 seconds with clean overalls or kitchen paper. If your knees are wet, the bedding is not dry enough.

Drop knee test

Crouch and then drop to your knees. Any pain reaction in your knees will quickly tell you how comfortable the beds are. If it hurts, it is likely the cows will be reluctant to use this area.

Find out more information about cow flow, housing systems, design, slurry and waste management.

Useful links

Loose yard management to control environmental mastitis in dairy cows

If you would like a hard copy of the Control of environmental mastitis guide please contact publications@ahdb.org.uk or call 0247 799 0069.