- Home

- Knowledge library

- Beef cattle: Understanding how each abattoir works

Beef cattle: Understanding how each abattoir works

There are differences between abattoirs, so ask what processes they do as it will affect the price they offer.

Back to: Selection for slaughter

While hitting the correct specification is key for your chosen market, it is important to understand such things as payment grids and dressing specifications, to help you compare which outlet can give you the best return for your stock.

All abattoirs will have a range of customers they supply and, thus depending on these markets, their pricing structure may vary.

Also, keep an eye on market prices to help you make informed marketing decisions by tapping into the latest information, including:

- Trends in the domestic beef market

- Up-to-date liveweight and deadweight prices

- Estimated weekly slaughter throughputs

- Latest retail prices

- Consumer purchasing trends

Pricing grids

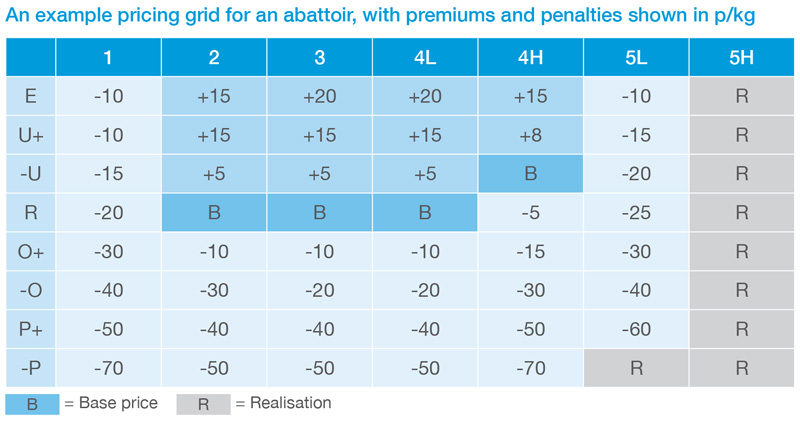

Different processing plants operate different payment systems. When comparing deadweight prices, it is important to understand the pricing basis and be aware of any potential weight or out-of-specification penalties.

Most plants will use a pricing grid that coincides with the EUROP classification grid and set a base price with bonuses and deductions depending on how your animals classify.

All abattoirs will have an upper and lower weight limit. Cattle falling out of the weight range will usually attract a penalty. Sometimes, this can be severe, so check before sale.

Hot weight rebates and rounding

Larger abattoirs in the UK (those slaughtering more than 20,000 cattle a year) reduce the hot carcase weight by 2%, to establish the cold weight (payment weight) to the supplier. However, while some lower throughput abattoirs have adopted the 2% hot weight reduction, others may continue to use the historical reductions based on the following:

|

Side weights (kg) |

Rebate per side* (kg) |

|

Up to 125 |

2.0 |

|

125.5–150 |

2.5 |

|

150.5–200 |

3.0 |

|

200.5 and over |

3.5 |

*rounded down to 0.5 kg

You should enquire which hot weight rebate method is used at the abattoir to which cattle are sent.

Abattoirs that apply the 2% hot weight reduction must record the actual hot weight shown on the scale (scales may be calibrated to 0.1 kg, 0.2 kg or 0.5 kg but no rounding must be applied to the indicator weight). Abattoirs continuing to use the historical table of rebates are likely to still round hot weights down to the nearest 0.5 kg.

Dressing specifications

When comparing grid prices between abattoirs, check that the dressing specification is the same. For a carcase of 320 kg, payable weight can differ by an average of 9 kg depending on the dressing specification used (from spec 1 to 3).

There are three dressing specifications approved for use in the UK.

|

Dressing specification |

Cod/udder fat |

Crown fat |

Thin skirt |

Bed fat |

Brisket fat |

|

1 Standard specification |

On |

On |

On |

On |

On |

|

2 EC reference specification |

Off |

Off |

Off |

On |

On |

|

3 UK specification |

Off |

Off |

Off |

Off |

Off |

In most cases, carcases are dressed excluding kidney knob and channel fat.

The following weight reductions are for a typical beast. Carcases with excess fat will have higher weight losses.

Standard Specification to EC Specification

- Males – 1.2%

- Females – 1.7%

EC Specification to UK Specification

- Males – 0.8%

- Females – 0.8%

Standard Specification to UK Specification

- Males – 2.0%

- Females – 2.5%

Killing-out percentage

Killing-out percentage, or KO%, is the carcase weight as a percentage of liveweight. It should not be confused with meat yield, which is total percentage of saleable meat from a carcase.

Factors affecting KO% are:

- Breed

- Gender – young bulls have a higher KO%

- Feeding system – KO% is lower when cattle finished off grass rather than indoor fed

- Time when weighed – gut full or empty

- Clean or dirty

- Careful handling – bruising can lead to condemnation of parts of the carcase

It can be a useful guide to assess performance, but only if used consistently across animals.

Useful links

Topics:

Sectors:

Tags: