- Home

- Knowledge library

- Using the EUROP grid in beef carcase classification

Using the EUROP grid in beef carcase classification

Find out how the EUROP grid, the 15-point grid and video image analysis (VIA) are used in beef carcase classification.

Back to: Beef carcase classification

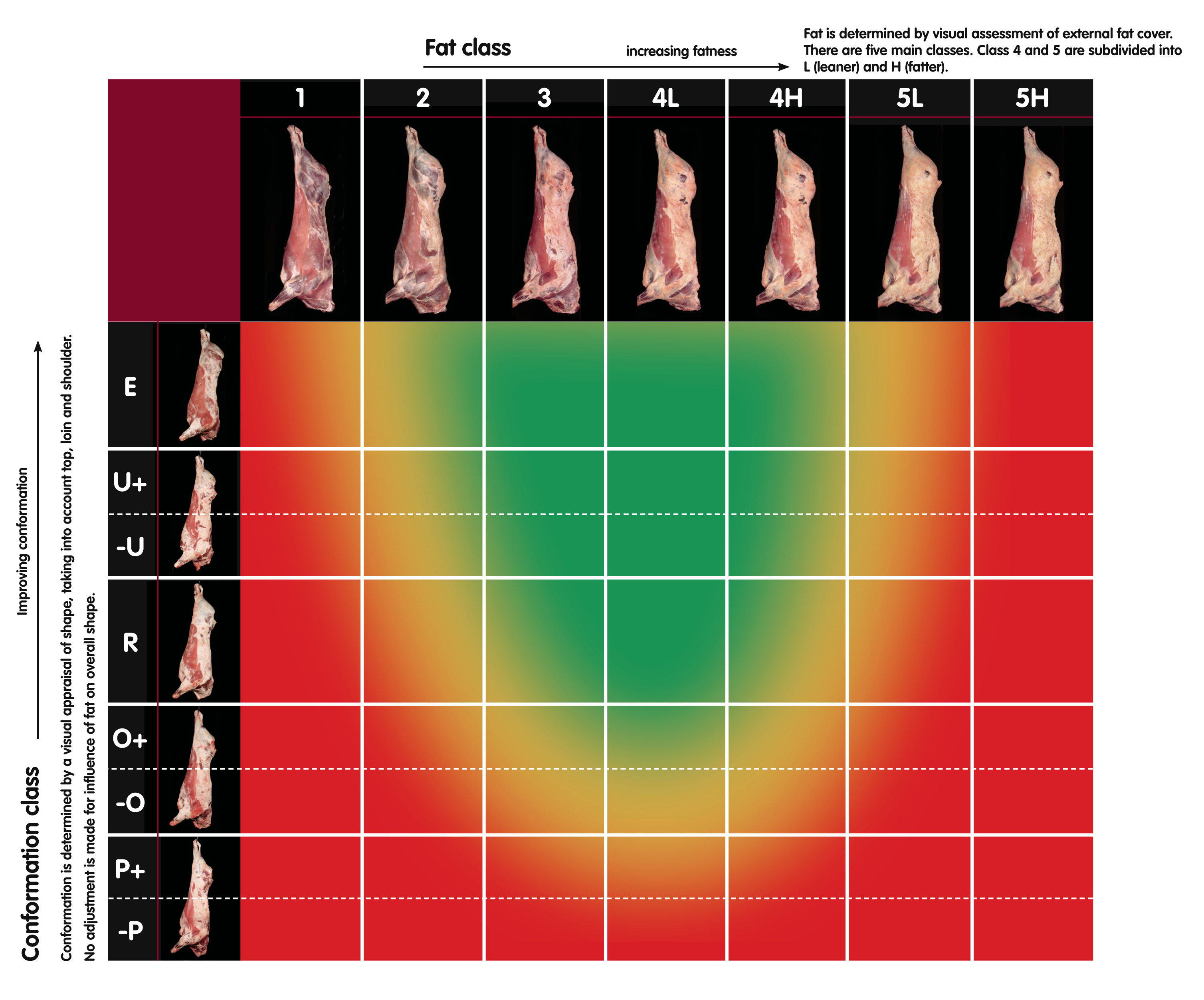

The EUROP grid is used to classify a carcase according to its conformation (shape) and fat level, on an alpha numerical scale. Combining scores for conformation and fat determines the market most suited for each type of carcase.

Any abattoir in the UK or Europe slaughtering 150 cattle or more per week is required to classify beef carcases. There are two grid variations of the grid used in the UK.

The traditional grid

The traditional grid is commonly used by most beef plants. Conformation is assessed on an E to P basis, with E being a convex and shapely carcase, R being an average shape or straight profile, and P being a plainer carcase with a concave profile.

Fat is assessed on a 1 to 5 basis, with 1 being very lean and 5 being very fat.

In the UK, conformation classes U, O and P are subdivided to give a high (+) or low (–) classification, and fat classes 4 and 5 are subdivided to low (L) and high (H). Overall, there are a total of 56 different carcase classifications.

Aim for animals to fall within the green shaded area where there is greatest demand and highest prices.

The 15-point grid

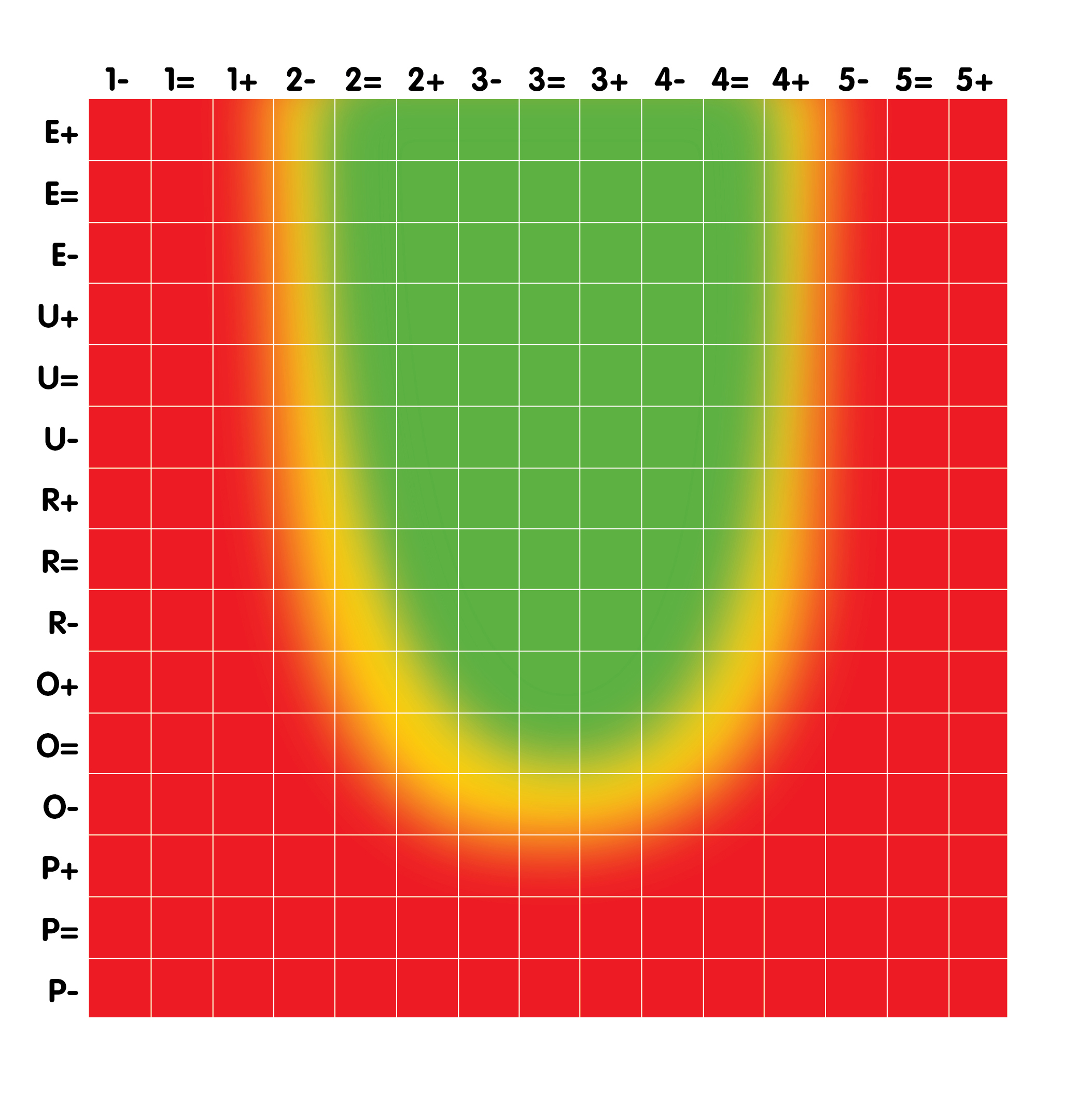

To further enhance the classification system, some abattoirs have adopted a 15-point grid, in which each conformation and fat class is subdivided into three: low (-), medium (=) and high (+) classes.

This grid gives a total of 225 potential classifications compared with 56 under the traditional grid. This could be useful in better informing all concerned on the types of carcases available, which could have potential financial benefits for the supply chain.

Carcases classified by Video Image Analysis (VIA) technology will be assessed against the 15-point grid. There are also a small number of abattoirs where the 15-point grid is used, and VIA is not in operation.

Video Image Analysis (VIA)

VIA is an automated method of classifying a carcase.

Machines are integrated into the slaughter line, usually near the scale point. One side of each suspended carcase is illuminated, and digital images are captured and processed using specialised software to extract data that relates to conformation and fat cover, such as length, width, angles, areas, volume and colour. The machine can interpret both the 2D and the 3D records.