- Home

- Knowledge library

- Youngstock housing case study – Eldon Farm

Youngstock housing case study – Eldon Farm

Stephanie Eldon and her family farm a unit with 199 dairy cows in Northern Ireland, producing 75 heifers calving into the herd per year. It is a Holstein closed herd calving all year round, with a 305-day average yield of 8,896 litres (L).

The original calf-rearing facility was not big enough, with persistent scours and high vet bills. It was damp, dark, and difficult to successfully rear the calves. The new shed was finished in December 2015, providing housing for 48 calves with peak calving in October.

The building in detail

Building specifications

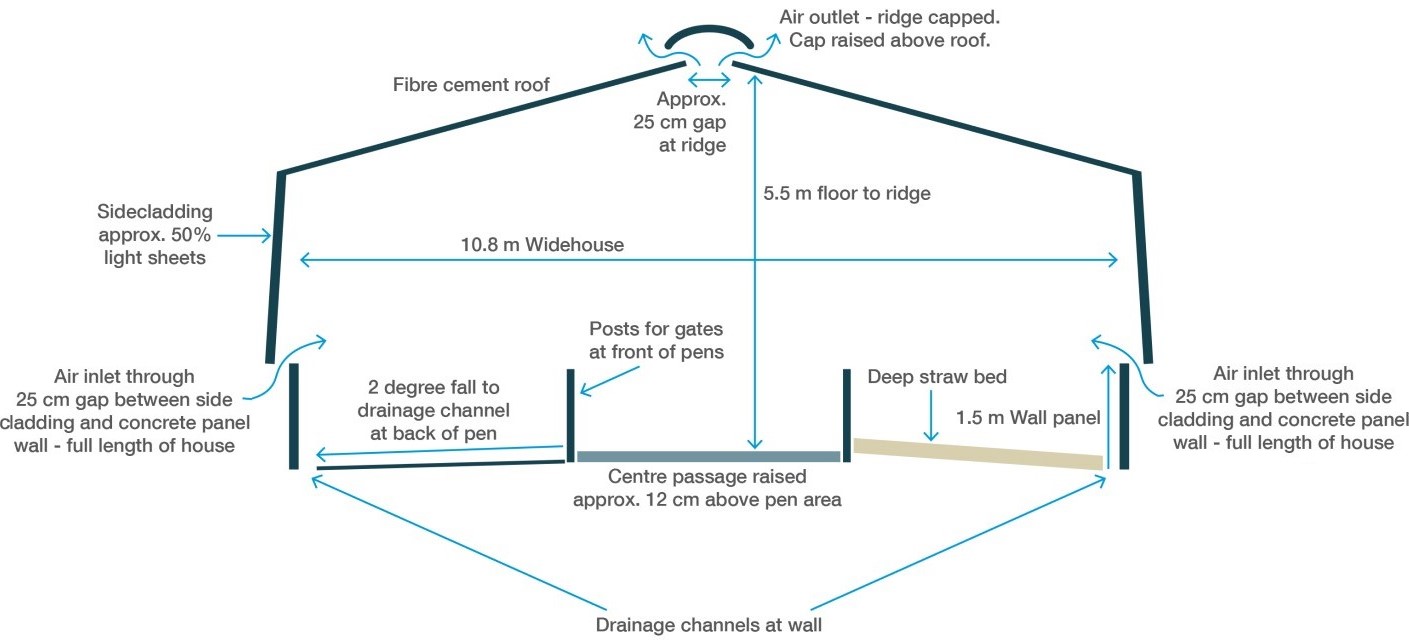

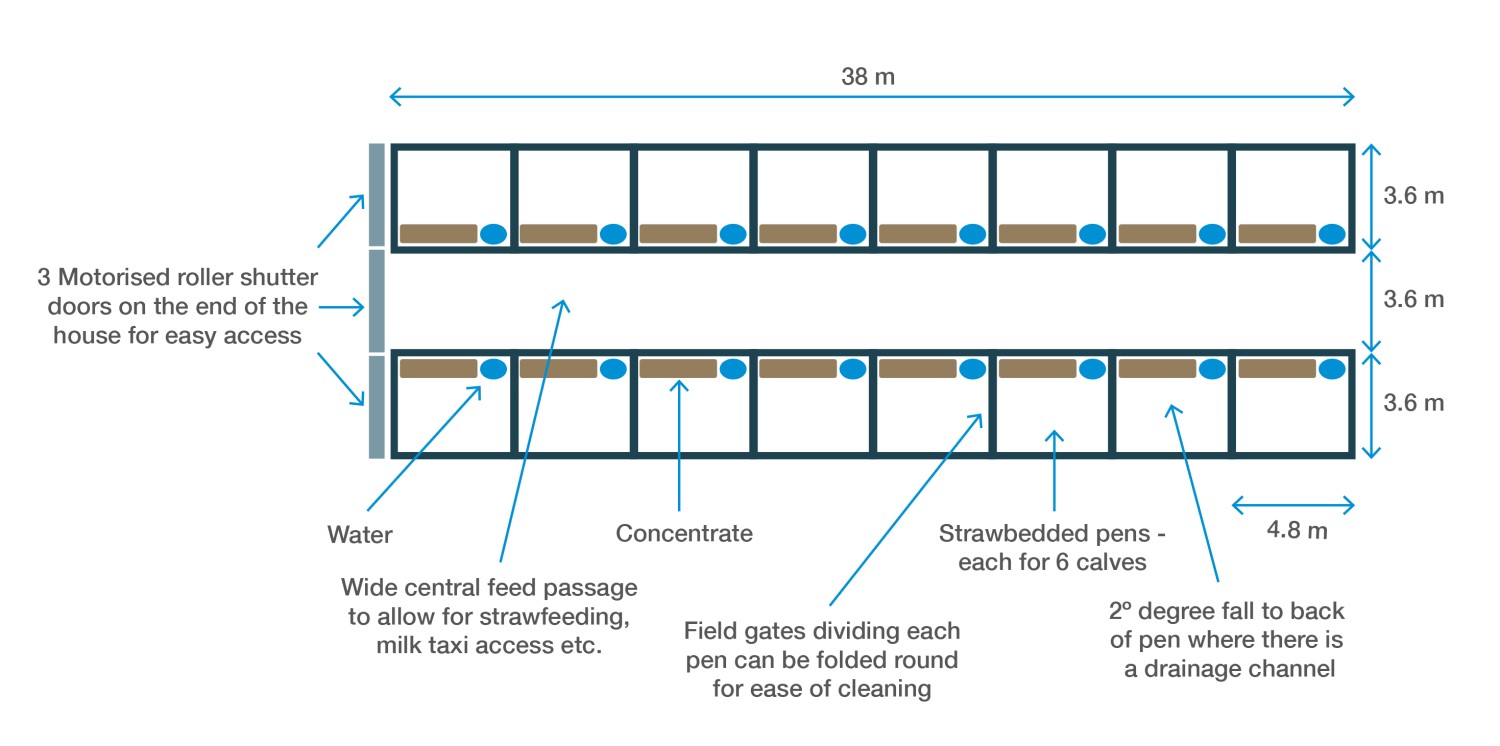

Stephanie’s building is a group pen system housed within a conventional building 38 m x 11.5 m. It has a bespoke concrete floor and concrete panels as the sidewalls. The floor has a 2% slope to a drainage channel at the back of the pen, and the centre pass is stepped 125 mm above the pen floor level to minimise the amount of straw coming out of the pens.

The concrete panels are easy to clean, with a 250 mm horizontal gap at the top of the pen wall at a height of 1.5 m, protected by solid cladding above. The wall cladding is mineral fibre with approximately 50% translucent sheets to the eaves at 4.05 m. The outlet area in the ridge is 38 m x 0.25 m = 9.5 m2.. The standard smoke clearance time during testing was 80 seconds.

There was no original mechanical ventilation, but Stephanie felt that the ventilation needed help at times. Subsequently, a positive pressure tube ventilation (PPTV) has been installed below the covered open ridge. There is still some condensation forming within the tube for the first 5–6 m that Stephanie wants to resolve.

The roof cladding is mineral fibre at a 15-degree pitch, with no roof lights. There is 50% translucent sheeting on the wall cladding, which provides a high degree of natural light.

The lighting levels were:

- Outside – 4300 lux

- Inside, light on – avg. 264 lux

- Inside, light off – avg. 134 lux

Building blueprints

Blueprints of Eldon Farm have been drawn up (see below). These have not been produced by architects and have been created by AHDB to reflect the design on the ground. They should not be used as complete plans, and you should always seek the advice of a qualified architect before designing and constructing buildings.

Eldon Farm aspect

Eldon Farm internal layout

Calf management

Stephanie tried using isolation pens in the past but was concerned about stress on the calf. Instead, her aim is to spot issues as quickly as possible and treat them before they become a problem.

Her protocol is:

- Calves treated with an antibiotic and non-steroidal anti-inflammatory if seen blowing within first few days

- Calves are provided with a jacket for the first three weeks of life in the winter

- Vaccinated using a Bovine Respiratory Syncytial Virus, Parainfluenza-3 virus and Mannhaemia haemolytica combined vaccine, and an Infectious Bovine Rhinotracheitis (Bovine Herpes Virus-1) vaccine

Calf feeding

The water supply for the calves is from Stephanie’s own source, with single bowls placed at the front of each pen with no plug. There is a flow rate of 916 ml/minute. The bowls are disinfected after each batch of calves has gone through.

Calves are fed with 4 L of colostrum within 2 hours of birth. Stephanie follows a strict colostrum management programme, and each collection is tested with a refractometer. Only colostrum >20 BRIX is frozen for future use.

Milk is given in multi-teat buckets, with six in a pen. Whole milk is fed twice daily, with 8 L/calf/day at days 0–69, 4 L/day on days 70–76, and 2 L/d on days 77–84. Milk is stored and delivered using a milk taxi. Ad-lib straw is fed as roughage from birth to day 70, with silage fed from day 70 onwards.

Biosecurity

Stephanie’s farm has a closed herd status. There is a clear procedure for cleaning out the pens once the calves are weaned, which is approximately four times per year after each batch has come through. The procedure is:

- Cleaned out

- Power hosed

- Disinfected using a disinfectant that targets coccidia and cryptosporidium as recommended by the vet

An entire half of the calf housing is cleaned at one time. All areas are cleaned, with gates pulled back, with a power wash on day one, followed by cleaning and disinfection on day two. There can be problems with having enough time to do this. Sometimes calves are not moved out of the building when they should be because the next space in the system is full. This can lead to a backlog and disrupt the cleaning schedule.

Milk buckets are cleaned after every feed with hot water and disinfectant, and water bowls are cleaned after every batch using a disinfectant.

Visitors are not given access to calving pens or calf houses.

Labour requirements

Stephanie is the main calf-rearer, with her son stepping in once a week. Three hours per day is given to feeding the calves, 30 minutes for cleaning equipment and 30 minutes on other calf-house-related tasks.

Stephanie does not rush her calves at feeding and will get meal and straw for older calves while letting younger calves drink milk. She feels that this allows for good observation of all calves and that the time spent gives her excellent payback.

Thoughts on the facility

Stephanie feels that with the calf housing system that she has in place, she can rear her calves the way she wants to. Calves thrive better in groups (they were previously housed in single homemade pens). Now, they are in single pens for a week only. The gates used as pen dividers could be higher so that they can be opened between pens to allow adjacent groups to mingle in the post-weaning period. However, to achieve this, they would need to be hung 125 mm higher.

During the design process, Stephanie specified that she wanted the centre pass to be 250 mm higher than the pen bottom so that straw could not creep out of the pens on to the pass. She was talked out of it as an additional cost that might not be worth it and ended up with a 125 mm rise. If building the facility again, she would go ahead with a 250 mm rise on the centre pass. She has also, with the use of the facility, installed a positive pressure tube ventilator to improve the ventilation. Some condensation is appearing in the tube and needs understanding and sorting out.

Read more about youngstock housing

Legislation and market requirements

Temperature, humidity and ventilation

Housing layout and construction

Designing housing to feed calves with ease