- Home

- Knowledge library

- Manure and slurry for clover

Manure and slurry for clover

Find out how slurry application methods influence clover production.

Nutrient management

Generally, little fertiliser nitrogen (N) is needed on swards with an appreciable clover content. On average, a good grass and clover sward (30–40% of dry matter of clover) will give an annual dry matter yield equivalent to that produced from about 180 kg N/ha applied to a pure grass sward. It is often difficult to decide how much nitrogen will be supplied because the clover content can be very changeable from year to year and within a given season.

Applications of fertiliser nitrogen to grass/clover swards should be made with caution because any form of mineral nitrogen inhibits nitrogen fixation by rhizobia in the clover nodules. There is also a risk of the grass responding to the nitrogen and shading out the clover, which can reduce the percentage of clover in the sward. However, some nitrogen may need to be applied to grass/clover swards to encourage early spring or late autumn growth:

- Apply up to 50 kg N/ha in mid-February to early March if early grass growth is required

- Apply up to 50 kg N/ha in late July or August if autumn grass is required

Clover is particularly sensitive to nitrogen application during establishment. No nitrogen should be used during this period. Do not apply high levels of nitrogen if a silage crop is taken from a grass/clover sward where the clover content needs to be maintained. Do not apply any fertiliser nitrogen for red clover or lucerne conservation.

Losses from leaching, run-off or to atmosphere mean that not all nutrients in slurry/manure are available to the plant. Losses depend on manure type, DM, application time and soil type. Consult a FACTS qualified adviser for further advice.

Lucerne and red clover crops have no requirement for nitrogen fertiliser, apart from that needed for establishment in low SNS soils (up to 50 kg N/ha). For red clover and grass swards, there may be some advantage in applying a small amount of nitrogen (up to 50 kg N/ha) in the early spring if the grass appears to be nitrogen deficient.

Low potash supply can restrict the growth of clover, even when there seems to be enough for grass. If the sward contains both grass and clover, then it is even more important to correct low soil potash indices.

Phosphate is also critical for nitrogen fixation. Clover growth is often limited in low phosphate situations. To decide whether and how to apply – and subsequently reapply – manure and slurry, the nutrient content should first be analysed in a laboratory using near-infrared spectrometry (NIRS). Equipment is also available for on-farm testing to give an instant assessment. In general, the thicker the slurry, the more nutrients it will contain.

Typical values of manures (fresh weight basis)

|

Manure type |

Dry matter (%) |

Nitrogen (kg N/t)* |

Phosphate |

Potash |

||||

|

Total phosphate (kg P2O5/t) |

Availability (%) |

Available phosphate (kg P2O5/t) |

Total potash (kg K2O/t) |

Availability (%) |

Available potash (kg K2O/t) |

|||

|

Cattle farmyard manure* |

25 |

6.0 |

3.2 |

60 |

1.9 |

9.4 |

90 |

8.5 |

|

Cattle slurry* |

6 |

2.6 |

1.2 |

50 |

0.6 |

2.5 |

90 |

2.3 |

|

Sheep farmyard manure* |

25 |

7.0 |

3.2 |

60 |

19.0 |

8.0 |

90 |

7.2 |

*Values vary depending on the dry matter %, age of the manure/slurry, soil type and season in which it is spread

Slurry application

Slurry must be applied at a sufficient rate to meet the phosphorus requirement of clover and optimise contribution to a mixed sward. Early growth and fixation from white clover is important to achieve a balanced sward. This means that nitrogen applications in early spring should be limited – later nitrogen applications (July/August) should not be necessary in a clover-rich sward and would discourage nitrogen fixation.

Differences in growth patterns (i.e. the fact that grass grows earlier in the season than clover) mean that careful consideration must be given to nutrient applications. Heavy applications of nitrogen early in the season have detrimental effects. Small strategic applications (up to 50 kg/N/ha) can encourage grass growth without detrimentally affecting clover growth.

Avoid smothering grass and clover because this can lead to lower intakes and the potential growth of undesirable bacteria, such as clostridia, entering the silage clamp at second cut. It is also important to minimise disturbance to clover stolons – particularly during the first 18 months after establishment.

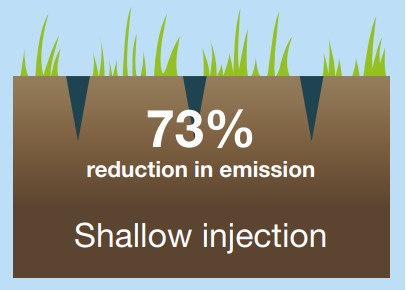

Injector systems apply slurry evenly without contaminating field margins and pose minimal risk of surface run-off. Injectors also help to break up areas of soil compaction, while eliminating damage to soils and worm populations that can be caused when slurry puddles at the surface. Slurries with less than 6% DM should be injected into the soil to make the most of the available nitrogen. Injection may be less suitable earlier in the season, both from an economical point of view and because coulters cut through the clover stolon network, which leads to setback. Repeated use may have damaging effects. Deep injection machinery can handle larger volumes of slurry, but is often restricted to certain soil types.

Band spreaders apply slurry in strips on the surface. They are only effective when used on short swards and may make the slurry vulnerable to losses. Trailing shoe machines operate with taller sward covers; slurry is distributed underneath the sward to prevent ammonia loss. Both the trailing shoe and band spreader can be used on any soil type, but, like the shallow injector, are limited to applications below approximately 35 m3/ha (3,200 gal/acre).

Source: Misselbrook et al., 2002

Useful links

How to assess the clover content of your pastures

Learn more in Nutrient Management Guide (RB209) Section 2 Organic materials

Read the Nutrient Management Guide (RB209) Section 3 Grass and forage crops

Read the Establishing and growing clover guide

If you would like to order a hard copy of any of the following, please contact publications@ahdb.org.uk or call 0247 799 0069:

- Establishing and growing clover guide

- Nutrient Management Guide (RB209) Section 2 Organic materials

- Nutrient Management Guide (RB209) Section 3 Grass and forage crops

The information in these web pages was sourced from Germinal, Grassland Development Centre (IBERS, University of Aberystwyth) and Charlie Morgan (GrassMaster Ltd).

Topics:

Sectors:

Tags: