- Home

- Knowledge library

- How to ensure energy efficient milk cooling

How to ensure energy efficient milk cooling

Learn the key aspects of configuring and running an energy efficient milk cooling process and refrigeration system, from pre-cooling to heat recovery and simple maintenance.

The biggest use of electricity

Electricity for milk cooling is typically the largest single usage on a dairy farm, accounting alone for over one third of consumption. Whilst the principle of milk cooling is straightforward, the equipment used and its efficiency can vary widely between farms, dependent on size, age, location, and so on. We look at the key aspects involved in achieving an energy efficient milk cooling process, whatever type of refrigeration system you use.

Cooling speed and timing is critical

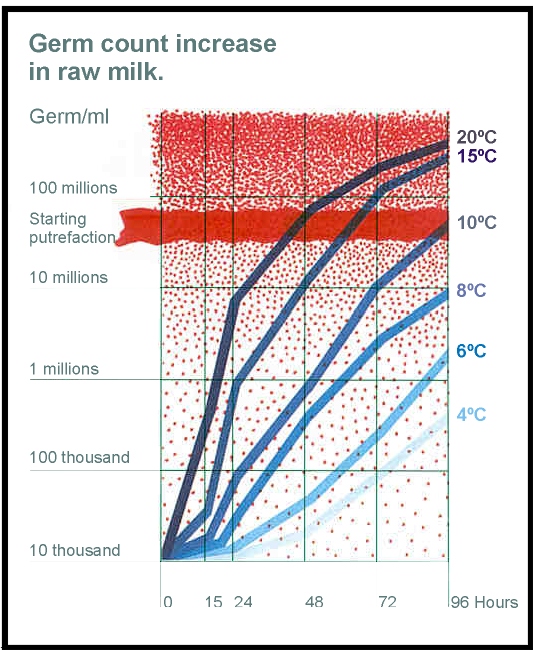

Cooling time is a critical factor in reducing bacteria growth in milk:

- At 21°C, actively growing bacteria will double in number every 20 minutes, and putrefaction may begin in under 2 days

- At 15°C , this doubling will take place in around 3 hours, and milk will begin to putrefy after around 60 hours, so this level of cooling is inadequate

- At a mechanically cooled 4.5°C, doubling may take perhaps 30 hours, and milk may be stored for days if necessary

Therefore, milk must be cooled from 37°C to 4°C as quickly as possible, ideally within 30 minutes of completion of milking, to minimise the increase in total bacterial count.

Figure 1: Germ count increase in raw milk

The advantages of milk pre-cooling

How pre-cooling using a plate heat exchanger reduces electrical demand and speeds up final cooling.

Find out more about pre-cooling milk

Core components of mechanical milk cooling

An overview of mechanical milk cooling and the refrigeration cycle, comprising condenser, evaporator and compressor. Plus Coefficient of Performance (CoP) explained.

Get an overview of mechanical milk cooling

How to maintain refrigeration system efficiency

Simple maintenance tips that help keep your dairy refrigeration system running efficiently.

Read out five top tips to keep your system efficient

How to benefit from heat recovery

A look at the cost savings you can make by recovering and using the heat rejected during the milk cooling process.