- Home

- EU PiG – Rearing pigs with intact tails

EU PiG – Rearing pigs with intact tails

Tail docking has been banned in Finland since 2003, so the Sikana Oy farm rears its 2,980 finisher pigs with intact tails and uses a number of practical measures to ensure they comply with legislation and maintain both welfare and productivity.

Ambassador: Tiina Puska, Finland

Publication date: May 2018

Theme: Animal welfare

Challenges: Tail docking

Rearing pigs with intact tails is possible in every country by taking care of pig health and welfare, minimising stress caused by competition for feed and water resources, and introducing correct management measures, such as ensuring appropriate environmental conditions, supplying appropriate enrichment materials, maintaining good health status or balanced diet. It is, therefore, advisable to monitor the risk factors by keeping detailed records of the husbandry conditions of the pigs.

“In my daily work, I see an intact tail as a huge advantage rather than a handicap. The intact tail is more like an 'animal welfare fever thermometer', monitoring the daily health and wellbeing of our pigs. The pigs' tail position and absence of tail-biting behaviour in the boxes tell me that everything is okay and my pigs are happy and growing well. This is because practically all actions that we are doing to preserve the intact tails are also beneficial for the excellent production results that we have. It is also rewarding to look at our well-growing and satisfied piglets, knowing that we have done everything right every day.” Tiina Puska

Rearing pigs with intact tails in practice

Pigs are housed in groups of 10 pigs per pen, with 1/3 slatted floor and 2/3 solid floor with heating. Further management practices include:

- Installation of heating pipes on the wall and negative pressure ventilation

- Pens have two pieces of chewable wooden activation toys, and pigs are provided with wood shavings twice a day as enrichment material

Production results

The unit is able to comply with regulations on leaving tails intact while maintaining welfare and productivity. The unit’s production results are good. Examples from 2016 are:

- Average daily weight gain from 30 kg to slaughter was 1046 g/d

- The production cycle was 12.9 weeks

- 2.5% condemnations due to tail biting

- Liquid feed is supplied five times per day, and the trough (>30 cm/pig) is never totally empty. All pigs can eat simultaneously. Feed consumption is checked daily, and supply adjusted as needed

- Pigs always have access to water that is quality analysed regularly

- Health status is high (national SPF: freedom of enzootic pneumonia, swine dysentery, atrophic rhinitis, mange, PRRS, Aujezky disease and zero tolerance of salmonella); the piggery is divided into two buildings which have several compartments. There is separate equipment in buildings, and boots are changed between buildings for biosecurity

Case studies

Technical reports

EU PiG

EU PiG

Two pieces of chewable wooden activation toys with wood shavings

EU PiG

EU PiG

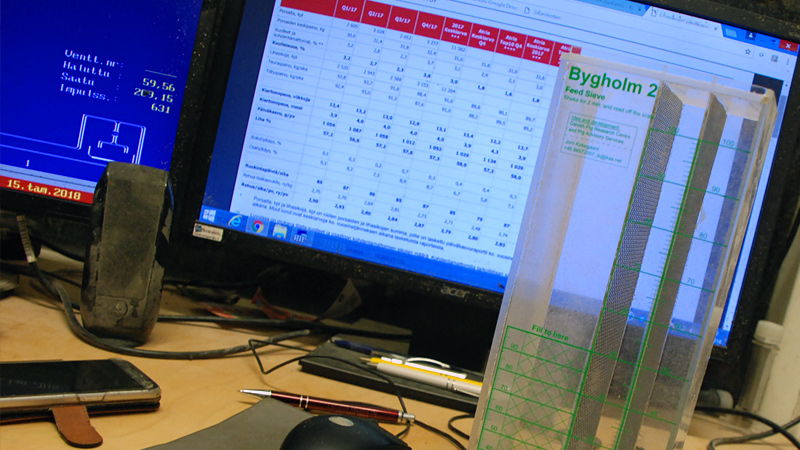

The coarseness of grounded grains is checked every two weeks with Bygholm 2 sieve.

Animal welfare best practice challenges

Strategies for dealing with piglets from hyperprolific sows

Strategies to reduce aggression between animals

The quality of the farm atmosphere

Contact us

To access more information, contact (RPIG Finland): Taneli Tirkkonen or EUPig@ahdb.org.uk

This project has received funding from the European Union`s Horizon 2020 research and innovation programme under grant agreement No 727933.

Government logo

Government logo