Blocking feet to manage lameness

Thursday, 26 August 2021

Vet Nick Bell shares his tips for using blocks on feet to treat lameness.

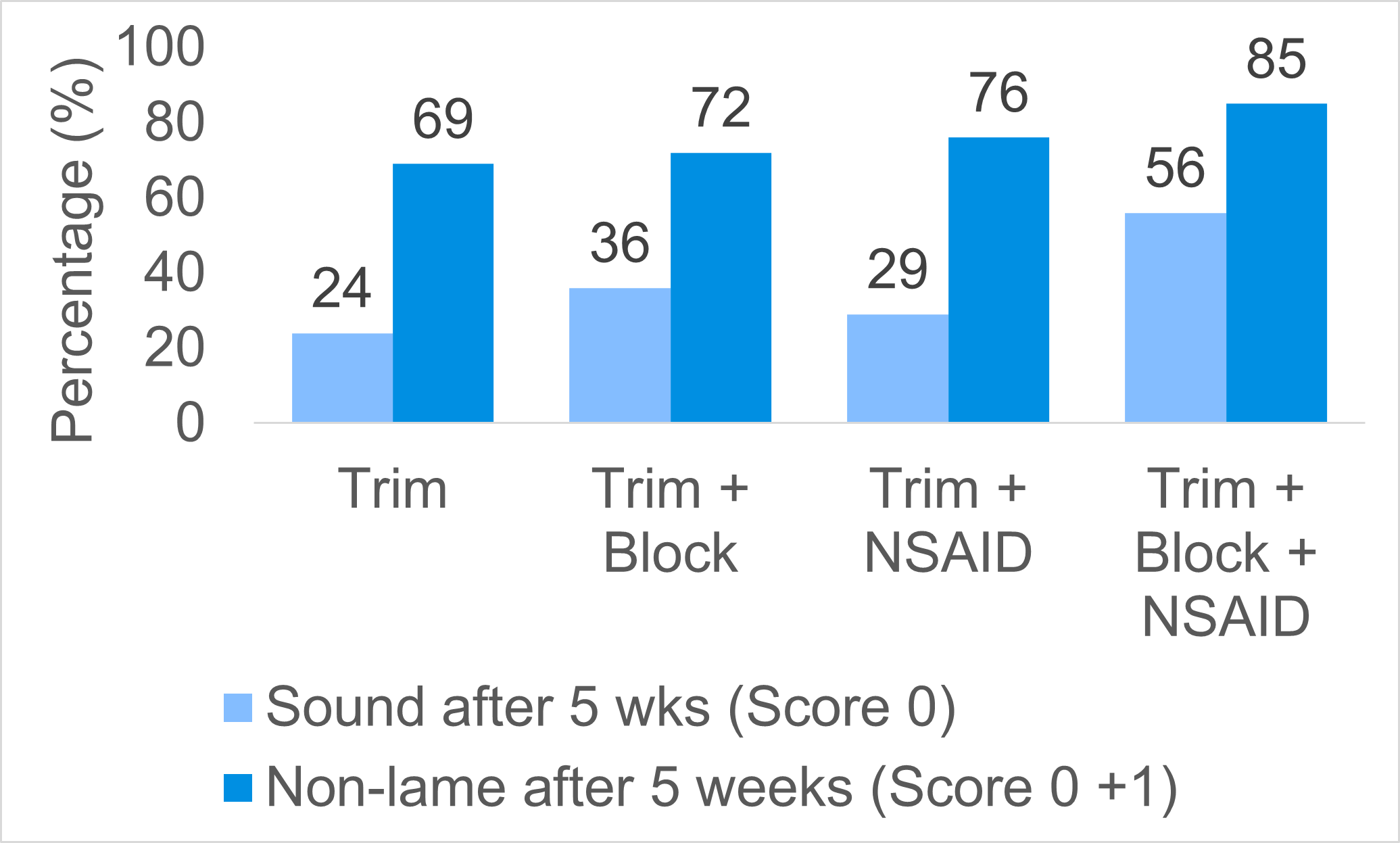

An AHDB funded trial at Nottingham University showed 5-week cure rates rose from 69% for “trim only” to 85% for trim, plus block and anti-inflammatory drugs (NSAID) (Figure 1). The block lifts the affected claw off the ground, giving a degree of rest from weight-bearing and lifting the claw out of the slurry.

The anti-inflammatory (NSAID) works well to counter inflammation, which includes bruising under the newly block claw as the cow adjusts to it. NSAID may be necessary to restore optimal blood flow to the bruised claw quickly.

The AHDB trial involved wooden blocks glued to the walls and sole using a traditional methylmethacrylate (putty-type) glue. This short article explores a range of blocking options and practical considerations when blocking lame dairy cows.

Figure 1. Recovery rates for cows randomly recruited to four treatment groups: a. Trim only b. Trim plus wooden block c. Trim plus 3 days of non-steroidal anti-inflammatory (NSAID, ketoprofen) d. Trim, block and NSAID. Work funded by AHDB, conducted by University of Nottingham and published by Thomas et al 2015.

Shoes

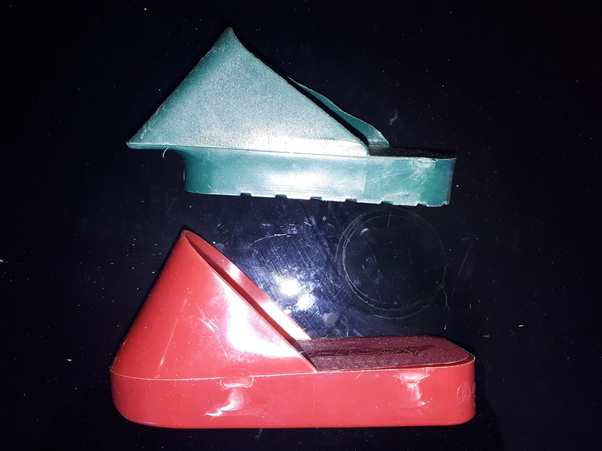

There are several shoes available on the market, including the Cow Slip (Figure 2) and the Demotec green shoe (Figure 3). The Accu block (Figure 2) offers the option of acting like a shoe or plastic block. Probably one of the main advantages of the shoes is their high retention rates.

The large contact area made between glue and walls around the toe of the block means they invariably stay on for at least 6 weeks and therefore they need to be removed. If left on too long then some cows can start to rock back on their heels, particularly if the shoe is a little short or if there is a toe lesion, risking permanent damage to flexor tendons.

They can be challenging to remove too. However, the adhesion to the wall makes them the preferred block for some people (e.g. Roger Blowey) and they can be very good for beginners who might only apply the occasional block. The main tip is to ensure the block is large enough for the foot and is firmly pushed onto the toe so the block sits over the heel.

The Demotec block has a base set back from the toe to help achieve this, whereas the CowSlip does not, which is a source of frequent criticism. There are several strengths and weaknesses of shoes summarised in Table 1.

|

Pros |

Cons |

|

Large contact area for better retention rates and wall weight-distribution |

Blocks can be more difficult to fit. You have to have some skill to position the block correctly over heel, and you need to watch the toe is well trimmed to achieve this and avoid a block sitting at strange angles. Cow Slips can be prone to rocking back on heels especially if there is a toe lesion. |

|

Plastic is resistant to wear from sand and concrete |

They can have a tendency to stay on too long. The Cowslip can deform allow the cow to rock back on the heel. Therefore, some cows can damage tendons if blocks are not removed after 4-6 weeks |

|

|

Blocks can be difficult to remove |

|

|

You need to carry different sizes, and blocks specific to match medial or lateral claws for a foot. |

Table 1. Pros and cons of the shoe.

Figure 2. A Cow Slip. Note the long block which covers the heel, the good alignment with the axial wall and how the block is pushed tightly onto the toe.

Figure 3. The Demotec Green block (top) and the Accu block (bottom). Note the rolled toe and wedge shape of the Accu block to enhance foot angle and improve locomotion. Most trimmers remove the plastic toe cup, but these can be useful if extra glue contact area is required.

Wooden blocks

Wooden blocks tend to be more versatile, coming in a variety of shapes and sizes. Firstly, length can vary from 120mm (heifer/small cow) through to 140mm (for big bull or for a “heel extension if a cow has a bad toe lesion). Thickness can vary from 10mm to 22mm. You can have beech or hard-wearing oak blocks, and blocks can be wedged from toe to heel.

They can be fixed to the sole and wall with a putty type methylmethcrylate glue which forms a shoe; or just fixed to the sole and sole-surface of the wall with a two-part polyurethane glue in a glue gun. The latter is very quick and easy to use and preferred by almost all professional trimmers.

The forces associated with weight-bearing do get transferred to the wall like a cow naturally walking on concrete, but not as much as with the putty or plastic shoe, unless you incorporate a plastic toecap like the Bond365 (Figure 4). In terms of size a shape, the larger thicker blocks are better for the more severe lesion, especially those in the toe.

The wedge blocks are ideal for lesions in the heel like a sole ulcer or white line. Cows have been shown to walk better on the wedged block and blocks appear to wear more naturally too. The main advantage of the wood is they can be modified (i.e. blocks shaped after setting, such as rolled toe) and they wear away within 4-6 weeks.

Therefore, you don’t generally need to worry about blocks remaining on too long – the exception perhaps being a thick block on the outer hind claw during hot weather when cows are much more susceptible to heel ulcers. Wooden blocks are also very easy to remove if necessary by splitting along the midline with nippers cutting along the groove-lines at the heel.

Figure 4. Bond 365. A plastic toe cup can be useful to increase contact surface area around the toe for better retention and weight-distribution. These are probably ideal for beginners and vets who do not want to carry bulky glue-guns. The occasional trimmers routinely use this type of block.

Plastic blocks

There are a few simple plastic blocks to be aware of. The “Accu block” is almost indestructible and has been praised for being the block you could put on a cow that needed a block for the rest of her life (usually short life). They are so tough that many slurry pumps and separators become blocked by them so check a farm slurry system can cope.

The thinner “Accu slips” (Figure 5) don’t seem to block slurry systems in the same way and work well for thin soles, particularly working bulls and to apply to wooden blocks to stop them wearing abnormally e.g. on sand units or cows with toe lesions which wear heels down.

Figure 5. Accu slip on a cow needing a thin block. This cow was recovering from Foul, which had led to under-run of the heel of the medial (inner) claw on the right of the picture. The block looks poorly aligned with the axial wall but this was due to poor camera angle (poor photographic skills - honest).

Polyurethane blocks

In the last 3 years there has been a revolution in “rubber blocks”, made from polyurethane. These are soft and flexible, which gives the cow considerably more comfort than the traditional wood or plastic blocks. Consequently, many lame cows walk exceptionally well on them.

The standard TP block is 14mm thick compared to 20-22mm for standard wooden blocks, but you can get a selection of thicknesses and shapes. The TP block come with different degrees of softness from purple (very soft), blue (soft) and orange (slightly firmer).

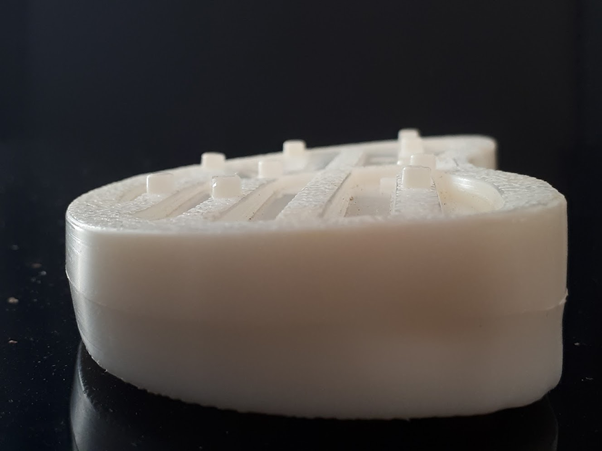

The orange TP blocks (Figure 6) tend to be most popular, as the softer blue blocks can be so flexible that they peel away from the glue. The Smartblock offer a wedge from toe to heel and axial-to-abaxial wall which enables a lot of height difference with a relatively thin block.

They also have spacer nipples to ensure an ideal thickness of glue is preserved between block and sole as you apply pressure during bonding. All the polyurethane blocks resist wear and retain their shape in all environments but this does mean they need checking and removing (or replacing) if still present after six weeks to prevent problems due to blocks staying on too long.

There is a knack to getting the polyurethane blocks to stick and it’s likely to be down to the silicone coating used to help release the blocks from the moulds. If you use a flame or heat gun to scorch the surface the block then silicone is removed and retention rates are generally very good.

Some people dab the scorched surface with paper towel to increase tackiness prior to bonding. There are now biodegradable versions available too. The TP and Smartblocks are a true revolution in block technology and if you are serious about treating lame cows then they should be in your kit.

There are also combinations of rubber/plastic and wood to get the best of both materials (i.e. glue bonds to wood well and lack of flex protects the bond; rubber offers cushioning and resistance to wear).

Figure 6. Polyurethane blocks are cushioned and durable (resisting wear). The authors observe cows walk exceptionally well on these.

Miscellaneous specialist blocks

Occasionally you will encounter a cow with lesions on both claws and you want to protect the foot and redistribute weight away from the lesions. Some European colleagues use re-enforced bandages (with duct/duck tape or silage wrap repair tape), or resin casts but there are three simpler alternatives to consider which are less prone to getting moist.

The first is the Shoof (Figure 7) which is a whole foot block. There is a knack to keeping these on but with the right string tension they can stay on for a few days (although it has been a while since I have used one). There is also the plastic “iron block” which is a horse-shoe. This can be cut to size to suit the cow foot and site of lesions.

The third option is to cut some of the very soft blocks (purple/blue TP or Shoofease) to size, avoiding the lesion(s). It’s important to say these blocks are used as salvage procedures, so the welfare of the cow needs careful monitoring (close veterinary supervision) and their use indicates problems that generally carry a poor prognosis.

Figure 7. The shoof (left) and “Iron block” (right) can be options for salvage situations.

Common faults to avoid

Finally, some farmers dislike blocks because there has been a problem encountered in the past. If standing times are very long then cows can readily bruise under the blocked claw so that ought to prompt a discussion, along with a review of blocking technique, choice of blocks, recheck protocols and NSAID use. Here is a summary of the important tips:

- Choose the right size/style of block and set blocks so they cover the heel. You want to avoid a pressure point in the middle of the heel by using a block of the appropriate length i.e. some glue must extend past the junction between zone 4 and 6 to minimise risk of heel ulcers, but not into the soft heel bulb

- Avoid having a block angled inward axially. Modify blocks to enhance foot angles if you have an inward angle (you can even create an outward angle like the Smartblock – Figure 8)

- Use plenty of glue so the block bonds to the sole and wall, but avoid glue pressing into the soft heel bulb (do not apply glue in the rear quarter of the block apart from a bit at the wall and allow the squeeze to press glue towards the heel).

- Make sure the block does not catch or rub on the other claw by aligning the inside of the block with the axial wall

- Apply some pressure for the first 30 seconds as the glue sets but not too much to squeeze all the glue out from under the block. The nipples on the Smartblocks are designed to prevent this (Figure 8).

- Store glue at a warm, not hot, temperature. Use a flame or heat gun to warm the block, dry the sole and help the glue set once bonding.

- Allow enough setting time. Most blocks require 3-4 minutes to set fully, so make the decision to block early, trim out the lesion and other feet while the glue sets. Some blocks will shift in position if the glue has not fully set.

- Record the application and ask the farmer to schedule a 6 week recheck date so blocks don’t stay on too long. The recheck can be in the crush or a “pre-check” at milking and segregate for the crush as necessary.

Figure 8. The polyurethane Smartblock – note the inner (axial) to outer (abaxial) wall wedge which increases the elevation of the painful claw (in addition to a heel-toe wedge). Note the nipples to protect glue depth.

Sectors: