- Home

- From Gilt Watch® to SmartPork

From Gilt Watch® to SmartPork

Discover how SmartPork can improve overall gilt and sow retention to produce marginal gains.

Gilt Watch® demonstrated there are many solutions to improving overall gilt and sow retention but only when embedded across processes to produce marginal gains. What is needed is a how-to guide for getting from variation to standardisation.

Road map to marginal gains

It is often difficult to take a step back and look at individual processes within pig production because there is always something to fix or prevent from breaking down.

This firefighting often consumes management time and labour, which is always in short supply. Taking a step back and using a management technique such as lean management is a bold step but, taking the time to do so, is a proven way of finding the time to fire fight less and achieve more.

SmartPork will take the findings of Gilt Watch® and other programmes that looked at heavier weaner weights and combine them with lean management.

Supported by a lean consultant proficient in agricultural production, producers will look at their processes and how to seek marginal gains (improvements) and, importantly, cement that practice as ‘standard’, i.e. how to standardise production processes.

Total Productive Maintenance

Gilt Watch® demonstrated that the solutions to retaining gilts and sows neatly, align with a manufacturing tool known as Total Productive Maintenance (TPM). In simple terms, TPM aims to embed standard processes that save time later.

It’s the equivalent of checking the oil, greasing hydraulics and performing 100-hour checks on a tractor so it doesn’t break down and cost you more in time and labour later.

In TPM, the sow is the ‘machine’ of pig production, in the same way a tractor or robot or printing press is for other tasks and industries. That means that machine is the main productive element and, therefore, the welfare and state of repair (health) of the sow is crucial to productivity.

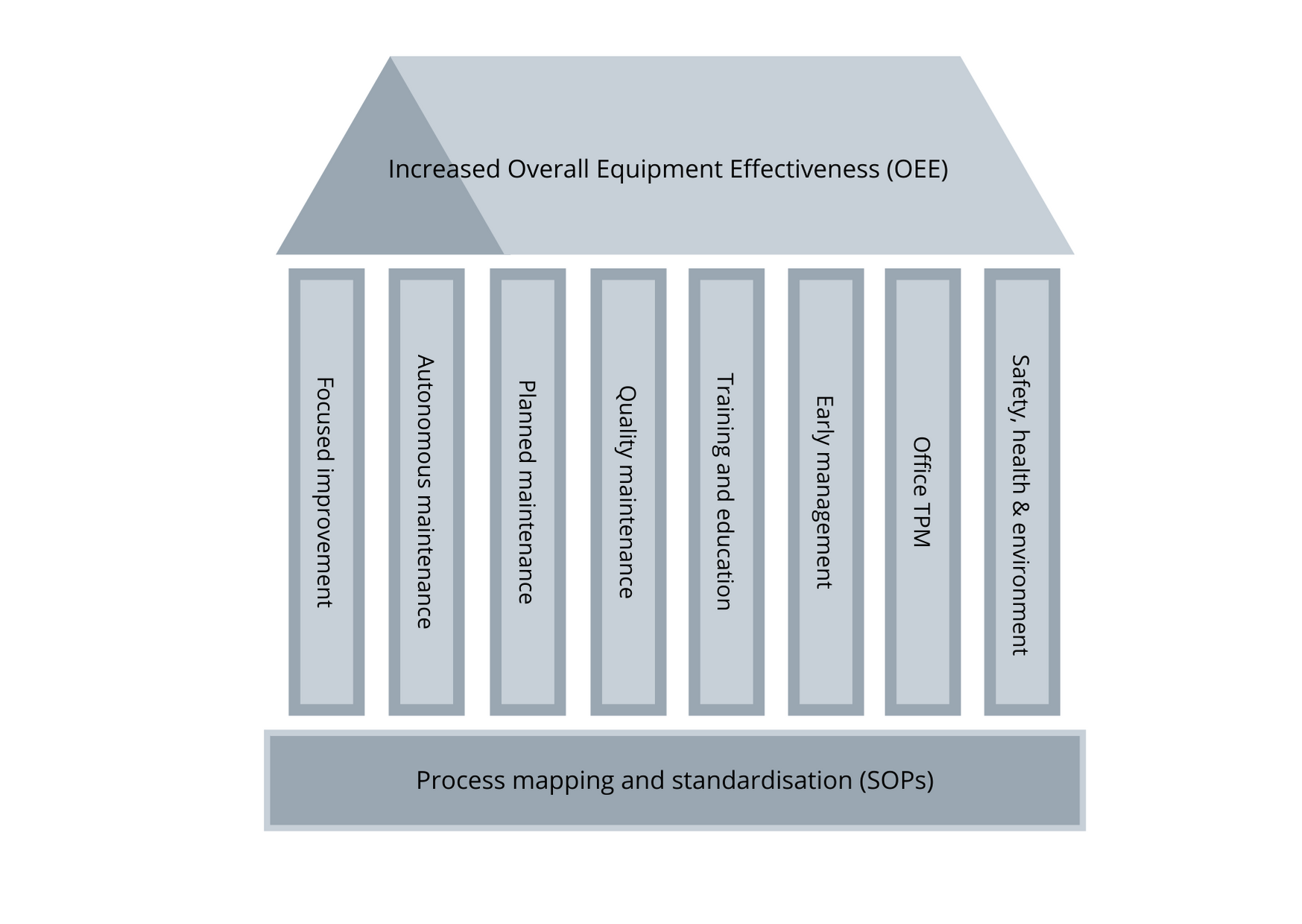

Eight pillars of effective TPM

TPM uses 8 pillars to ensure effective machinery maintenance (see below):

Examples of TPM in pig production are plentiful, a few of these are discussed below:

Focused improvement

Deliberate shift in diets at different parities, this may be a simple change in volumes or a more complex analysis of the mineralisation and overall nutrient contents.

Autonomous maintenance

From simple combination vaccines that protect sows against multiple disease in a single dose to more complex systems such as sow feeders that record weight and tailor diet according to the individual. Autonomous data capture is part of maintenance and supports additional pillars such as Office TPM. Using data collected on piglets to automatically change approaches to the gilt and sow in subsequent parities. This is described in more detail in the EUPiG case study: The KALINAT approach.

Planned maintenance

Deliberate reviews of sow condition including checks on udder health, body condition score (BCS), with follow-up changes to process, i.e. low BCS results in a change in diet or additional feed. Routine vaccinations and other health interventions are also considered planned maintenance.

Quality maintenance

Use of piglet data to assess the quality of the gilt or sow; this would be data in addition to number and survivability. Accurate weights at birth and weaning have a substantial impact on the ability to assess gilt and sow performance. Rather than weighing all piglets and averaging the weight, which hides the outliers. Random litters from the farrowing batch should be weighed to monitor variation and recorded against the parity of the sow. This will allow producers to build a typical variation pattern by parity. This can be used to further refine the balance of parities in each farrowing group.

Training and education

Technician effect or stockperson effect has been found to be a major contributory factor across multiple pig production processes including AI and farrowing. The use of lean management and monitoring of skills training using staff CPD systems such as PigPro allow managers and staff to identify gaps in their skills at a personal and business level.

Early management

Arguably one of the most important factors of successful gilt management. Making sure that gilts entering the breeding herd meet all requirements on confirmation, leg and udder health and, of course, BCS. Any animals that do not meet those standards should ideally be rejected from entering the breeding herd. Consistent records of ‘defects’ should be kept to feed back to the gilt supplier especially if that supplier is an internal GP herd.

Office TPM

Data is essential to monitoring business performance; automation of collection using RFID and mobile data collection makes collection in the breeding herd safer (wands provide additional distance from breeding sows), more accurate as people can make mistakes in recording IDs and events, unlike machines, and more timely. There is less need to write down data, transport it across the business and wait for someone to enter it into a system for analysis. The data should be analysed to show the outliers – those animals that underperform and those that overperform. The underperformers are those likely to need further planned maintenance. The overperformers support genetic improvement as part of the GP herd and can cause issues themselves, i.e. sows that produce routinely heavier piglets are likely to cause variation in the finishers, with heavy pigs that may run to fat before the rest of the batch can be viably sold.

Safety, health and environment

At the sow level, this is provision of optimum conditions in terms of ventilation, feed access, floor surface and, of course, access to water systems. Overall welfare must be maximised because poor environmental conditions can cause ‘machinery’ breakdowns.