- Home

- EU PiG – DrySist: Truck dry disinfection

EU PiG – DrySist: Truck dry disinfection

The challenge was to improve the biosecurity against ASF and other pathogens (PRRS, salmonella, E.coli and swine dysentery) during animal transportation.

Ambassador: Spain

System: DrySist

Developing company: Techtrans System SL (OPP group)

Company using the system: Piensos Costa S.A.

Publication date: July 2020 | Theme: Health management

Challenges: African swine fever (ASF) biosecurity measures

Focusing the biosecurity concept exclusively inside the farm is a mistake, because truck movements are one of the most important sources of risk of disease entry for farms.

Improving biosecurity during transportation

Benefits

- Reduction in veterinary costs

- Exclusion of harmful pathogens such as ASF

Costs

- Electricity consumed: 8–10 kW/h

- Diesel consumed: 30 L/h

- Propane consumed: 37 kg/h

Using a truck thermo-assisted disinfection system

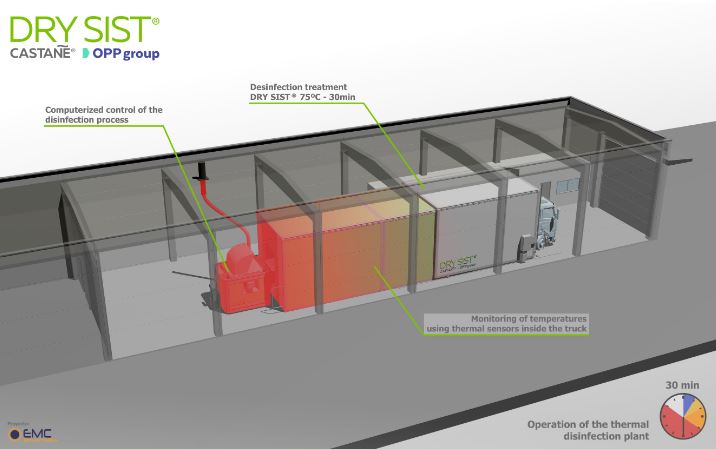

The process divides the disinfection into three parts: trailer, wheels and chassis and cabin. The process takes place inside an expandable tunnel. The truck's cabin is manually disinfected following the PED disinfection protocol; the lower part of the truck is disinfected from the beginning of the process to produce a high penetration effect. The system is connected to the truck and pumps hot air into the container until it reaches 75ºC for 15 minutes. The whole process takes about 30 minutes and is electronically certified. The certificate can be received remotely in real time.

By increasing biosecurity, the entry of diseases (digestive and respiratory) on farms is reduced, and therefore, the use of antibiotics is also reduced. Once the disinfection system is implemented, the farm’s disease reinfection cycle is broadened from 1.5 years to 3 years, approximately. Finally, farm productivity (less diseases and mortality) and meat quality (food safety) are improved. Investment in innovative biosecurity systems, which reduce the use of water and time spent by personnel, has obvious benefits in increasing biosecurity, and, therefore, reducing the risk of disease outbreaks.

Case study

Technical reports

EU PiG

EU PiG

This company implemented a truck thermo-assisted disinfection system called DrySist.

EU PiG

EU PiG

Animal health best practice challenges

Use of slaughter data to improve health outcomes

Early warning of diseases and production errors

Influence of gut health on disease and production

Optimal vaccination strategies

Reducing antimicrobial medication

Contact us

To access more information, contact RPIG (Ireland): Ciaran Carroll or EUPig@ahdb.org.uk

This project has received funding from the European Union`s Horizon 2020 research and innovation programme under grant agreement No 727933.

Government logo

Government logo