- Home

- Projects

- Farm Excellence

- Pork Strategic Farm - Precision Pig

Pork Strategic Farm - Precision Pig

About Pork Strategic Farm - Precision Pig

- Precision Pig is a three to five-year project which began in 2019

- Find out how the data gathered from this programme, can deliver for the producer

- This technology helps to improve labour efficiency and productivity

In 2017, we funded a proof-of-concept trial looking at supplying traceable pork, from sow to finished pig and beyond, into the supply chain.

The key elements of the project were DNA sampling and radio frequency electronic identification (RFID) tagging to allow pigs to be given a unique identifier (UI), facilitating traceability throughout their production. Tissue samples taken from carcases at the abattoir could then be traced back to their birth sow using their DNA.

The trial raised some opportunities to investigate the potential for a step change in traceability and precision livestock production; the Precision Pig project was formed.

The Precision Pig programme has four-focused project aims:

-

Test the use of RFID ear tags on finished pigs as they go through the abattoir on a normal production run, week after week

While RFID tags were used successfully with the progeny of a limited batch of sows (60), it did not test the abattoirs (processors) in a typical production run.

Our next step is to see if the reading of RFID tags can be replicated, at least in terms of UIs, on a day-to-day basis in plant with batches from an individual farm being processed during a normal kill day, week after week. -

Link health data (alongside carcase data) gained at the abattoir to individual pigs and feed back to the producer

The Pig Health Scheme provides an opportunity to gain health data and feed the results back to producers on a subset of individual pigs.

This could be cross-analysed with production data, the electronic Medicine Book (eMB) and other health interventions during production to put a value on any losses/rectifications to the producer.

-

Test the use of RFID ear tags on farm with a variety of other technologies to further demonstrate their use

There are significant advancements in on-farm automated technology, such as weighing systems, optical sorting, grading technologies and feed systems.

The incorporation of RFID tags and UIs into these systems will allow analysis of trends in pig performance at a level not currently used widely within the industry. -

Explore modelling on entire herd management data (including UI data) to predict desired outcomes, such as carcase weights, culling and health incidents

We tested modelling to produce a carcase weight prediction model that could be used to predict when pigs would reach a specific slaughter weight.

This would be useful for both producer and processor to predict throughputs. Other areas could be modelled to predict culling, health incidents, etc. using other production or environmental data, such as humidity or health interventions, feed intake and primal yields.

These areas take the project beyond the initial proof-of-concept stage. They start to embed RFID as a key tool for improving productivity through the supply chain and demonstrate the link between farm data and the tools producers can use to inform decision-making. It will also help us to collect data from our Strategic Farms and field trials in a consistent manner.

Plan

Health and disease control

Although we have good traceability using batches to date, the option to have individual identification using RFID would support any on-farm tracing of the root cause of unwanted health issues. Proof that antibiotic use meets the required levels for the food chain and export markets can be collected. Individual health treatments could also be recorded in the eMB.

Inventory management

Electronic identification can support inventory management when combined with herd software systems, in the same way it does for consumer-goods supply chains. The project will extend inventory management beyond the breeding herd to both the rearing and finishing herds and to an individual animal level.

Supply chain information and assurance

The project will enable supply chain data, such as carcase weight and fat depth (future primal yield data), and health data from the Pig Health Scheme/CCIR to be passed back to producers. At the individual level, these records could be linked to the building, pen and feed used during production. For the processor, the information would provide increased traceability and the ability to support marketing campaigns to retailers and consumers. Through greater efficiencies, it would lead to a more consistent product.

Continuous improvement or active management

One of the main aspects of continuous improvement is monitoring and benchmarking production data, both physical and financial. If done well, such analysis can highlight which areas of management and technologies are contributing to improved performance. RFID allows for data capture to be automated, which makes the data more robust and easier to analyse.

Benchmarking and trials

This project would underpin future work we carry out on both Strategic and Monitor Farms. Manual data entry is open to transcription errors, both in its capture and entry, this work would remove the potential for this type of error. This means that when we publish the results of any demonstration or trial work, we can be confident in the raw data.

Do

We have tested a range of radio frequency identification (RFID) and associated technologies in the field. Some of the key benefits of this technology, as well as areas to take note of, include:

- There are benefits and limitations of both ultra high frequency (UHF) and low frequency (LF) technologies, with UHF showing advantages in bulk read situations and LF showing advantages in reading specific individuals, from birth to weaning. The use of handheld electronic devices for data input saves time, increases accuracy and breaks down some of the barriers to implementing new data capture techniques in the field or barn

- Routine weighing of livestock allows rapid diagnosis of out-of-specification pigs, which could save the industry millions of pounds each year

- RFID increases the accuracy of routine weighing while reducing the labour burden

- Retention of ear tags is not just down to the correct application. The male components should be significantly shorter for piglets than for sows and have as narrow a central pin as possible

- It is possible to collect data routinely from sire to slaughter using RFID

Check

We have identified that current performance benchmarking needs to move away from only looking at average performance data and towards identifying outliers. Suppliers for the Precision Pig programme have been chosen specifically because of their visual reporting which helps to show clearly any outliers.

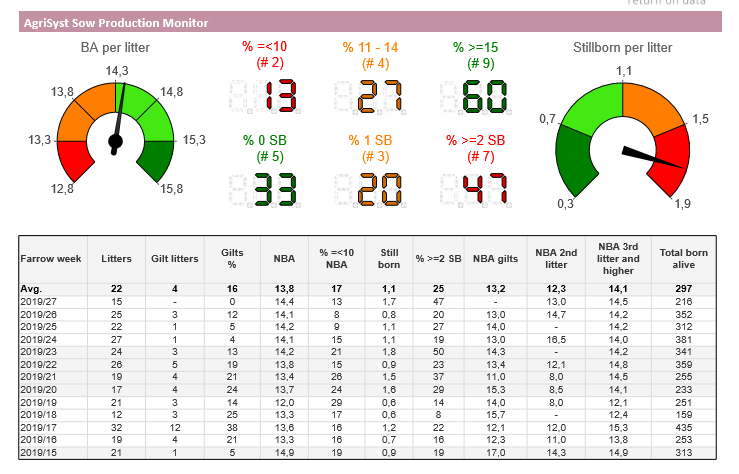

The image above is from an example of an actual production report – the average performance is shown, in this case for the number of piglets born alive. What is different are the colour-coded figures in between the speedometer-style averages.

Green numbers indicate animals exceeding performance – those that may be key for breeding replacements. The numbers enable you to analyse areas such as the differences between management techniques or for streamlining parity profiles.

The red numbers highlight the percentage of animals that underperform – those that would be culled.

The figures can be used as a management tool, to plan culling and breeding, as well as spotting where training and support are needed.

Act

With outliers identified, the reports and data can be used to target areas of production that are underperforming. This may be with further training, investment or a change in how labour is used across the business. It could be as extreme as a complete change in process or inputs. The data should always be reviewed with the wider farm management team and include specialists as required, such as the farm vet.

In addition to reacting to past batch performance, the data is being fed into a machine-learning algorithm by Newcastle University as part of a four-year PhD. The aim is to establish if the data can be used to predict future trends, for example:

- Could the final slaughter weight of a piglet be predicted at weaning?

- Could the herd retention of a gilt be predicted at parity 1 or 2?

- Can production and environmental factors be used to predict disease outbreaks?