- Home

- Reducing dairy electricity costs webinar Q&A

Reducing dairy electricity costs webinar Q&A

On 17 March 2021, John and Anna Booth from Rhual Dairy and technical speaker Jon Swain and Jonathon Sandercock from NFU Energy took part in a webinar focusing on improving energy efficiency and reducing electricity consumption and costs. Here, you can find the full list of questions along with Jon's and John & Anna's answers, taken from the webinar.

*Sgroliwch i lawr am y Gymraeg*

Is there somewhere that a farmer can get help to know what type of electricity contract they can be on? Is there a service available to inform farmers what the best would be for their business?

Here at NFU Energy we have a wealth of experience in helping farmers assess their needs and determine which electricity contract would best suit them. We also have group buying power which allows us to offer NFU members cheaper rates with some of the major utility providers, allowing farmers to receive better deals than they would normally as an individual.

Are there any KPI measures that farmers can quickly measure to determine where they stand with their energy usage.

Yes, you can get a measure of kilowatt-hour (kWh) per cow as an initial indication of energy performance. I would say as an average to high energy density would be between 400 kWh and 600 kWh per cow per annum, for benchmarking purposes. In this instance, the lower the figure, the better. You can see very low energy users at around 250-300 kWh per cow per annum, however farms in these scenarios will likely have a large proportion of renewables and low-cost heat recovery systems on their farms.

What temperature should milk be after it has left the plate cooler?

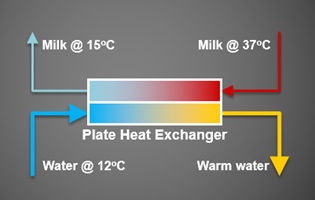

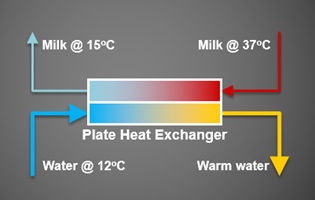

Cooling time is a critical factor in reducing bacterial growth in milk, therefore, milk must be cooled from 37°C to 4°C as quickly as possible, ideally within 30 minutes of completion of milking to minimise any risk. Typically, milk leaves the cow at 37-35oC, and it is recommended to get as much of a temperature drop as possible through your plate heat exchanger. You would like to see a 20oC drop in temperature, to get the milk down to approximately 15oC (if using borehole water only). This will reduce the energy consumption and run time of the bulk tank compressors. In a system with an ice builder and two stage plate heat exchanger, you would want to see a much larger drop in temperature, down to 7 degrees or less for the final milk temperature leaving the plate. If your system is not achieving this then an investigation of the milk to water flow rate ratio, and size of heat exchanger should be conducted.

For more information, please see the Milk Cooling Fact Sheet – available on AHDB GrowSave website.

For carbon foot-printing, are kWh produced from solar panels considered greener than from the grid?

If you think of the grid electricity you consume, that has around 220-250 grams of carbon dioxide per kWh associated with its production and transmission as it stands now. This has come down considerably less than 5-10 years ago, where it would have been around 400 grams of carbon per kWh. This is because the energy mix from the grid has diversified, becoming less reliant on coal, and using more sources of renewable energy such as wind and PV. With solar PV, or any other renewable generation, you are avoiding using the grid electricity and the carbon footprint associated with it, and whilst all renewable energy will have some carbon emissions attached to it (through production of the equipment, transport etc.), it will have significantly less carbon attached to it compared to grid supplied electric. However, it must be noted – if you produced renewable electricity and sold the surplus to your electricity supplier, you cannot take this as offset. For example, if you purchased 20,000 kWh from the grid and produced 10,000 kWh from renewable energy and then sold that 10,000 kWh – when you sell electricity, you are also selling the carbon credentials, so this does not reduce your carbon footprint.

If you make a vacuum pump variable, how does it affect the lifespan of the pump?

A variable speed vacuum pump should have a longer life than a normal pump because it is operating at a lower stress condition - the motor will be running slower than that of a normal pump. The only issue it may suffer is with the controller – the electronics box may need renewing during the pump's whole lifetime.

Mechanically, a vane pump does not like to reduce its running speed much more than 30%, but thanks to a disproportionate relationship between lowering pump speed against how much energy it uses, a large cost saving can still be achieved by adding a variable speed drive (VSD). For example, if you turn your vacuum pump down by ~20%, then you will reduce the energy consumption by ~50%, and reducing the speed by ~50%, will reduce energy consumption by ~80%. Even a small reduction in speed can lead to big energy savings.

The reason that vane pumps are typically not ideal for variable speed is because they rely on the rotation of the vanes to create an oil seal around the inner chamber to create a suitable vacuum. Slowing down the motor too much can cause this seal to fail, thus the pump will not create enough of a vacuum and it will not operate effectively. You can slow the motor down by approximately 30% without impacting the vacuum pump efficacy, however, as stated above, you can still realise substantial energy savings by this relatively small reduction in speed. Retrofitting variable speed drives onto vane pumps is still very feasible, provided the controller ensures a satisfactory minimum pump speed.

If you are considering a new pump/VSD setup, then a Roots Blower style pump could prove to be the best investment moving forward. These are much better suited to running at lower speeds, thus the variable speed drive can help achieve even larger cost savings. The drawback is the initial cost of these pumps being practically double that of a vane pump set, however, over 10 years, they should be cost comparable, and you also get the other benefits of a Roots Blower pump, such as less maintenance, less oil consumption and quieter operation.

We have a very similar cooling system to the farm in the talk today, only our ice bank has just broken, and our dairy service company are keen to sell us a glycol cooling system. Do you have any views on these?

Glycol chillers operate in a similar way to an ice builder; however, the cooling medium here is glycol in a closed system, rather than a continuous supply of water from the mains or a borehole. A glycol system can provide huge savings on water consumption, provided you could not make use of all the water you used previously with your ice builder. Another important thing to consider with a glycol chiller is that they use a large amount of instantaneous energy to cool the milk right down to 4oC by the time it leaves the plate heat exchanger. This would change your energy use profile over the course of a day. If your electricity connection can handle this, and you do not gain much benefit from using off-peak or renewable electricity, then it can be an effective way to cool the milk while using less water. However, one aspect that made these types of coolers attractive was that they were eligible to claim income on the government Renewable Heat Incentive (RHI) scheme. This has now come to an end so new installations will not be able to claim on these tariffs.

What benefits did John and Anna see from putting the lights in?

We put in LED lighting on a timer around 2 years ago – we saw the benefits almost straight away and we would not go away from this personally, because the cost of running the lights is so low. For us, yes, we would go for a patterned lighting system. We find the cow wellbeing has improved since using a patterned lighting system, as cows are calmer and quieter. We found that fertility improved with higher conception rates too. The other benefit we see is that the shed is a much nicer environment for us and our team to work in.

Can you get single phase variable speed vacuum pumps?

Yes, generally this involves a phase converter where you would end up with a three-phase vacuum pump with a single-phase phase converter, but of course this incurs more capital cost. Yes, it is possible, but it is not a common solution for farmers.

Is electric storage worth considering at, ie batteries?

It will be worth thinking about as costs for that technology come down – the economics works out favourable for very large-scale operation, especially in a situation where you can gain support payments from the National grid for helping them with their supply. I do not believe you can make the economics work on a dairy if you buy electricity cheap and use the stored energy when electricity is expensive. The other area where batteries can work very well, is where a farm may struggle with capacity i.e. looking at a challenging price for an upgrade in supply capacity, or if grid connection to your farm or building is not feasible for remote locations.

Can planning permission be difficult to attain with regard to wind turbines.

Yes – it can be very difficult. There is a strict planning permission regime due to the concerns regarding the environmental impact both in terms of wildlife and impacting views, which has led to a strict planning regime that can be a barrier to those wanting to apply for planning permission.

Cwestiynau ac Atebion

Oes ‘na rywle y gall ffermwr gael help i wybod pa fathau o gontractau trydan sydd ar gael iddyn nhw? Oes ‘na wasanaeth ar gael sy’n dweud wrth ffermwyr pa un fyddai orau ar gyfer eu busnes nhw?

Yma yn NFU Energy mae gennym gyfoeth o brofiad o helpu ffermwyr i asesu’u hanghenion a phenderfynu pa gontract trydan fyddai’n eu siwtio nhw orau. Hefyd, mae gennym bŵer prynu fel grŵp, sy’n caniatáu inni gynnig cyfraddau rhatach i aelodau NFU gyda rhai o’r prif ddarparwyr cyfleustodau, sy’n golygu bod ffermwyr yn cael gwell bargen nag y byddent fel arfer fel unigolion.

Oes ‘na fesurau Dangosyddion Perfformiad Allweddol (KPI) y gall ffermwyr eu mesur yn gyflym i bennu lle maen nhw arni o ran defnydd o ynni?

Oes, gallwch gael mesur cilowat yr awr (kWh) fesul buwch i gael syniad bras o’r perfformiad ynni. Mi fyddwn i’n dweud y byddai dwysedd ynni canolig i uchel rhwng 400 kWh a 600 kWh y flwyddyn fesul buwch, at ddibenion meincnodi. Yn yr achos hwn, po isaf yw’r ffigur, gorau oll. Mae defnyddwyr ynni isel iawn ar gael, oddeutu 250-300 kWh y flwyddyn fesul buwch, ond mae ffermydd gyda’r senarios hyn yn debygol o fod â chyfran uchel o ynni adnewyddadwy a systemau adfer gwres costau isel ar eu ffermydd.

Beth ddylai tymheredd llaeth fod ar ôl iddo adael y plât oeri?

Mae amser oeri’n ffactor hanfodol o ran lleihau twf bacteriol mewn llaeth, felly dylid oeri llaeth, o 37°C i 4°C, cyn gynted â phosib, ac yn ddelfrydol, o fewn 30 munud o orffen godro, i leihau unrhyw risg. Fel arfer, mae llaeth yn gadael y fuwch ar 37-35 oC, ac argymhellir y dylid cael y tymheredd i ostwng cymaint â phosib drwy’r plât cyfnewid gwres. Rydych am weld y tymheredd yn gostwng 20o, i gael y llaeth lawr i tua 15oC (os yn defnyddio dŵr dyfrdwll yn unig). Bydd hyn yn defnyddio llai o ynni ac yn cwtogi amser rhedeg cywasgyddion y tanc llaeth. Gyda system sydd ag adeiladydd rhew a phlatiau cyfnewid gwres dau gam, mi fyddech am weld gostyngiad llawer mwy yn y tymheredd, i lawr i 7 gradd neu lai ar gyfer tymheredd terfynol y llaeth sy’n gadael y plât. Os nad yw eich system yn cyflawni hyn, yna dylech archwilio cymhareb cyfradd llif y llaeth a llif y dŵr, a maint y plât cyfnewid gwres.

Am fwy o wybodaeth, gweler y Daflen Ffeithiau Oeri Llaeth – sydd ar gael ar wefan GrowSave AHDB.

O ran ôl troed carbon, ydy kWh a gynhyrchir o baneli solar yn cael eu hystyried yn wyrddach na rhai o’r grid?

Os feddyliwch chi am y trydan rydych chi’n ei ddefnyddio o’r grid, mae tua 220-250 gram o garbon deuocsid fesul kWh yn gysylltiedig â’i ddefnyddio a’i drawsyrru ar hyn o bryd. Mae hyn gryn dipyn yn is nag yr oedd 5-10 mlynedd yn ôl, pan fyddai wedi bod oddeutu 400 gram o garbon fesul kWh. Mae hyn am fod y gymysgedd ynni o’r grid wedi’i arallgyfeirio, gan ddod yn llai dibynnol ar lo, a defnyddio mwy o ffynonellau ynni adnewyddadwy megis gwynt a PV. Gyda phaneli solar PV, neu unrhyw fath arall o ynni adnewyddadwy, rydych chi’n osgoi defnyddio trydan o’r grid a’r ôl troed carbon cysylltiedig, ac er bod rhai allyriadau carbon yn gysylltiedig â phob math o ynni adnewyddwy (yn sgil cynhyrchu’r offer a’i gludo ac ati), mi fydd maint y carbon cysylltiedig yn sylweddol is, o’i gymharu â thrydan o’r grid. Fodd bynnag, dylid nodi – petaech chi’n cynhyrchu trydan adnewyddadwy ac yn gwerthu’r trydan dros ben i’ch cyflenwr trydan, ni allwch osod y naill yn erbyn y llall. Er enghraifft, petaech chi’n prynu 20,000 kWh o’r grid ac yn cynhyrchu 10,000 kWh o ynni adnewyddwy ac yna’n gwerthu’r 10,000 kWh hwnnw – drwy’r werthu trydan, rydych chi hefyd yn gwerthu’r manteision carbon, felly nid yw hyn yn lleihau eich ôl troed carbon.

Os drowch chi bwmp gwactod yn un cyflymder amrywiol, sut mae hynny’n effeithio ar hyd oes y pwmp?

Dylai pwmp gwactod cyflymder amrywiol fod ag oes hirach na phwmp cyffredin am ei fod yn gweithredu dan amodau straen is – bydd y motor yn rhedeg yn arafach nag un pwmp cyffredin. Yr unig broblem all godi yw’r rheolydd – gall fod angen adnewyddu’r bocs electroneg yn ystod oes y pwmp.

Yn fecanyddol, nid yw pwmp llafn yn hoffi gostwng ei gyflymder rhedeg lawer mwy na 30%, ond diolch i berthynas anghymesur rhwng gostwng cyflymder y pwmp â maint yr ynni a ddefnyddir, gellir arbed cost sylweddol o hyd drwy ychwanegu gyriant amrywio cyflymder. Er enghraifft, os trowch chi’ch pwmp gwactod i lawr ~20%, yna byddwch yn lleihau’r defnydd o ynni ~50%, ac o ostwng y cyflymder ~50%, byddwch yn lleihau’r defnydd o ynni ~80%. Gall hyd yn oed gostyngiad bach yn y cyflymder arwain at arbediad ynni sylweddol.

Nid yw pympiau llafn fel arfer yn ddelfrydol ar gyfer cyflymder amrywiol, am eu bod yn dibynnu ar gylchdroad y llafnau i greu sêl olew o amgylch y siambr fewnol i greu gwactod addas. Gall arafu’r motor yn ormodol olygu bod y broses selio hon yn methu, ac felly ni fydd y pwmp yn creu digon o wactod i redeg yn effeithiol. Gallwch arafu’r motor oddeutu 30% heb effeithio ar effeithlonrwydd y pwnc gwactod, ond, fel y nodir uchod, gallwch wneud arbediad ynni sylweddol gyda newid cymharol fach i’r cyflymder. Mae ôl-osod gyriannau amrywio cyflymder ar bympiau llafn yn gam ymarferol o hyd, cyn belled â bod rheolydd y pwmp yn caniatáu cyflymder isaf boddhaol.

Os ydych chi’n ystyried pwmp newydd/gyriant amrywio cyflymder, yna mi allai pwmp chwythwr gwreiddiau fod yn fuddsoddiad da ar gyfer y dyfodol. Mae’r rhain yn fwy addas o lawer ar gyfer cyflymder arafach, ac o ganlyniad gall y gyriant amrywio cyflymder arwain at arbediad cost mwy sylweddol. Yr anfantais yw cost gychwynnol y pympiau hyn, sydd ddwywaith cymaint â chost pwmp llafn. Fodd bynnag, dros 10 mlynedd, mi ddylent fod yn gymharol o ran cost, ac mae buddiannau eraill yn gysylltiedig â phwmp chwythwr gwreiddiau, megis llai o waith cynnal a chadw, defnyddio llai o olew, a rhedeg yn dawelach.

Mae gennym ni system oeri debyg iawn i un y fferm sy’n cael ei thrafod heddiw, ond mae ein banc rhew ni newydd dorri, ac mae ein cwmni gwasanaeth llaeth ni’n awyddus i werthu system oeri glycol inni? Beth yw eich barn chi am y rhain?

Mae oeryddion glycol yn gweithio mewn ffordd debyg i adeiladwyr rhew; ond mai’r dull o oeri gyda’r rhain yw glycol mewn system gaeedig, yn hytrach na chyflenwad parhaus o ddŵr o’r prif gyflenwad neu ddyfrdwll. Gall system glycol olygu arbediad enfawr o ran defnydd o ddŵr, cyn belled â’ch bod yn methu â gwneud defnydd o’r holl ddŵr roeddech chi’n ei ddefnyddio gynt gyda’ch adeiladwr rhew. Un peth arall pwysig i’w ystyried gydag oeryddion glycol yw eu bod yn defnyddio llawer iawn o ynni yn ddisymwth i oeri’r llaeth i 4oC erbyn yr adeg mae’n gadael y plât cyfnewid gwres. Mi fyddai hyn yn newid eich proffil defnydd ynni yn ystod y dydd. Os all eich cysylltiad trydan ymdopi â hyn, ac os nad ydych chi’n cael llawer o fudd o ddefnyddio trydan oriau allfrig neu adnewyddadwy, yna mi all fod yn ffordd effeithiol o oeri llaeth gan ddefnyddio llai o ddŵr. Fodd bynnag, un agwedd oedd yn gwneud y mathau hyn o oeryddion yn ddeniadol oedd y ffaith bod modd hawlio incwm ar gynllun Cymhelliad Gwres Adnewyddadwy’r llywodraeth. Mae hwn wedi dod i ben erbyn hyn felly ni fydd gosodiadau newydd yn gallu hawlio ar y tariffau hyn.

Pa fuddiannau welodd John ac Anna o osod y goleuadau?

Mi wnaethon ni osod goleuadau LED gydag amserydd tua dwy flynedd yn ôl – mi welson ni’r buddiannau ar unwaith bron a fydden ni ddim yn newid o hyn yn bersonol am fod cost rhedeg y goleuadau mor isel. I ni, byddem yn mynd am system oleuadau patrymog. Mae lles y fuwch wedi gwella ers inni ddefnyddio system oleuadau patrymog, am fod y buchod yn dawelach a mwy llonydd. Mae ffrwythlondeb wedi gwella hefyd, gyda chyfraddau beichiogi uwch. Y budd arall yw bod y sied yn amgylchedd mwy dymunol i ni a’n tîm weithio ynddo.

Allwch chi gael pympiau gwactod cyflymder amrywiol un cam?

Gallwch, fel arfer mae hyn yn golygu gosod trawsewidydd camau, a byddai hynny’n golygu bod trawsnewidydd un cam yn arwain yn y pen draw at bwmp gwactod tri cham, ond wrth reswm mae hynny’n golygu mwy o gostau cyfalaf. Ydy, mae’n bosib, ond nid yw’n ateb cyffredin ymhlith ffermwyr.

Oes yna werth mewn ystyried storio trydan, h.y. batris?

Mi fydd yn werth ystyried hynny wrth i gostau’r dechnoleg hon ostwng – mae’r economeg yn ffafriol wrth weithredu ar raddfa fawr iawn, yn enwedig gyda sefyllfa lle gallwch dderbyn taliadau cymorth gan y grid Cenedlaethol am eu helpu nhw gyda’u cyflenwad. Dwi ddim yn credu allwch chi wneud i’r economeg weithio gyda busnes llaeth os ydych chi’n prynu’r trydan yn rhad ac yn defnyddio’r ynni a storiwyd pan fydd trydan yn ddrud. Y maes arall lle mae batris yn gweithio’n dda iawn yw pan fydd fferm yn cael trafferth gyda chapasiti h.y. yn wynebu pris heriol am uwchraddio capasiti’r cyflenwad, neu os ydy cysylltu’r fferm neu’r adeilad â’r grid yn anymarferol mewn lleoliadau anghysbell.

Ydy hi’n anodd cael caniatâd cynllunio ar gyfer tyrbinau gwynt?

Ydy – mi all fod yn anodd iawn. Mae ‘na drefn lem yn gysylltiedig â chaniatâd cynllunio yn sgil pryderon am yr effaith amgylcheddol, yn nhermau bywyd gwyllt a’r ffaith eu bod yn amharu ar yr olygfa, sydd wedi arwain at drefn gynllunio lem all fod yn rhwystr i’r rhai sydd am wneud cais am ganiatâd cynllunio.