- Home

- Gilt Watch® Early Findings

Gilt Watch® Early Findings

Understand the importance of benchmarking to reduce the variation and increase the efficiency of pig production.

Gilt Watch® benchmarking has demonstrated that, despite the complexities of pork production, there are simple interventions and tasks that can have an impact on reducing the variation, increasing the efficiency of production.

The midpoint Gilt Watch® review

Gilt management is not a single process but multiple, complex interacting processes, starting at selection and continuing through to parity 2. At this point, gilt management does not stop but transitions into sow management, with some processes remaining and others becoming additional. Control and standardisation of these processes have been shown by producers to have substantial impact on overall business performance.

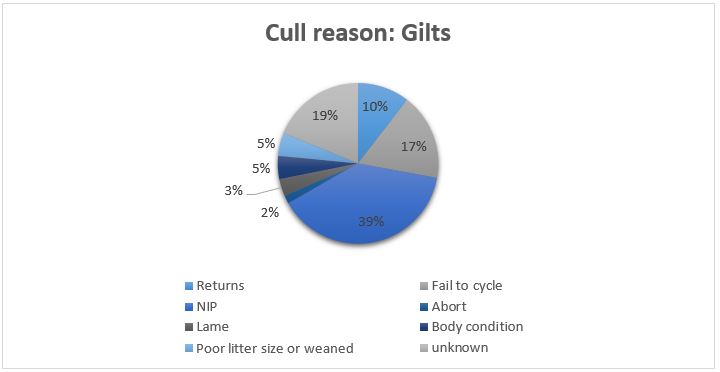

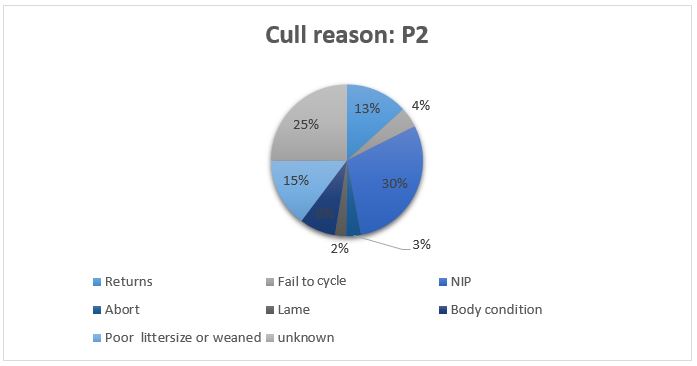

Gilt Watch® recording and benchmarking identified that the following factors are the most likely to lead to a gilt or sow being culled from the herd:

Solutions to retaining gilts and sows

Further work has been undertaken with industry to look at the likely adoption by producers and impact of solutions to the reasons for culling. These solutions were ranked by producers and allied industry (vets, nutritionists and geneticists) in terms of their potential impact. This was cross-referenced and correlated against available scientific literature to produce the following ranked solutions to ensuring good gilt and sow retention.

.png)

EUPiG case study – KALINAT approach

For both sow prolificacy (pigs born per litter) and parity, an average piglet weight to target (for each litter to achieve) is calculated, to guarantee the maximum survival of piglets. This target average weight comes from a huge database of farmers, working with Cooperative Eureden, who have weighed all the piglets at birth for several years.

The farmer records the piglet’s average birth weight of each sow and calculates the ratio between this value and a target weight based on best practice.

This ratio is called the KALINAT index. A KALINAT index over 1 is an indicator of a good quality birth piglet. The farmer in this case study had some sows (24%) with a low KALINAT index, so after weaning he gathered these sows and increased the quantity of feed during gestating period and until birth.

The increase in pigs born per sow (hyperprolific sows) has caused various production issues in relation to ensuring that the piglets have the best chance of survival and, in turn, becominga profitable animal.

Weighing of litters at birth is integrated into the usual care practices and does not take more time, except for the notation of the weight on the sow card.The farmer also identifies by coloured pencil the smallest piglets, to reinforce their monitoring during the lactation period.

Cost benefit

For someone not already using the practice, suitable weighing systems at birth that allow weights to be gathered as part of routine birth management tasks would need to be purchased – approx. 10,000 euros. Below are a list of benefits:

- 180 g increase in the average birth weight of piglets from sows with a low KALINAT index

- Reduction of the rate of losses on liveborns by 2.6%

- Proportion of sows with a low KALINAT index decreased from 24%–19%

- An increase of 1 pig produced/sow/year, i.e. a positive change in gross margin of 24,000 euros at the farm level (360 sows present) (Changes between 2017 and 2019 data).

Based on these assumptions, variable production costs after implementation of best practice decreased by 2.3% per piglet, mainly due to the higher piglet production per sow per year. A decrease was also observed in the case of fixed costs by 2.8% per piglet. As a result, the total costs were lower by 2.4%.