- Home

- Knowledge library

- Using livestock wastes for anaerobic digestion (AD)

Using livestock wastes for anaerobic digestion (AD)

Anaerobic digestion can help the agricultural sector move towards becoming net zero. It also offers other benefits to farmers and growers beyond a lower carbon footprint.

What is anaerobic digestion?

Anaerobic digestion (AD) is the breakdown of organic materials, often waste streams such as slurry and manure, by bacteria, to produce methane (biomethane or biogas). AD plants come in varying sizes, systems and approaches, with large-scale commercial systems generating substantial power that is sold into the national grid.

Large AD systems are subject to planning applications, business rates and other legal processes. Micro AD, or small-scale farm systems, are not subject to the same planning restrictions but do require a T24 waste exemption (anaerobic digestion at premises used for agriculture and burning of resultant biogas). These can be obtained by registering with the Environment Agency (EA). The spreading of digestate – an output from the process – requires a U10 waste exemption (spreading waste to benefit agricultural land).

Find out more about waste exemptions for Micro AD

Find out more about waste spreading exemptions

Most AD systems use a combination of inputs or feedstocks, including animal wastes, crop residues, ensiled crops and various other waste streams. This is because the microbes that break down these materials to produce methane (CH4) need a balanced input of nutrients. Livestock waste tends to be low in carbon but high in nitrogen, phosphorus and potassium. This imbalance can result in lower rates of gas generation and longer residency times in the AD system than if higher carbon feedstocks, such as crop residues or ensiled crops, were used.

For this reason, micro AD systems will use a range of solutions to optimise efficiencies, such as varying bacterial and enzyme cultures and changing the design and technology used for the digester itself. We recommend that you discuss your requirements with a reputable supplier and undertake a full quotation, including an estimated return on investment (ROI) and gas potential tests (BMP tests), to assess your likely output.

The benefits and uses of biomethane as a fuel

The methane (biomethane) produced in AD systems can be used in two ways:

- Burn in a combined heat and power (CHP) system to produce electricity and heat

- Extract as gas and use as a fuel, e.g. in new generation engines and trains

The most common use is in CHP systems. These produce electricity that is used directly on the farm and/or directed into the national grid. The input of electricity to the national grid is another route to realising a return on investment as inputs of electricity can yield a payment from Feed-in Tariffs (FITs).

The heat generated by the CHP system can be used to heat spaces such as calf housing, parlours and wash water, or other farm buildings. While not necessarily able to provide a payment in the form of a FIT, this heat can offset the cost of using gas or electricity to heat the same space or volume of water.

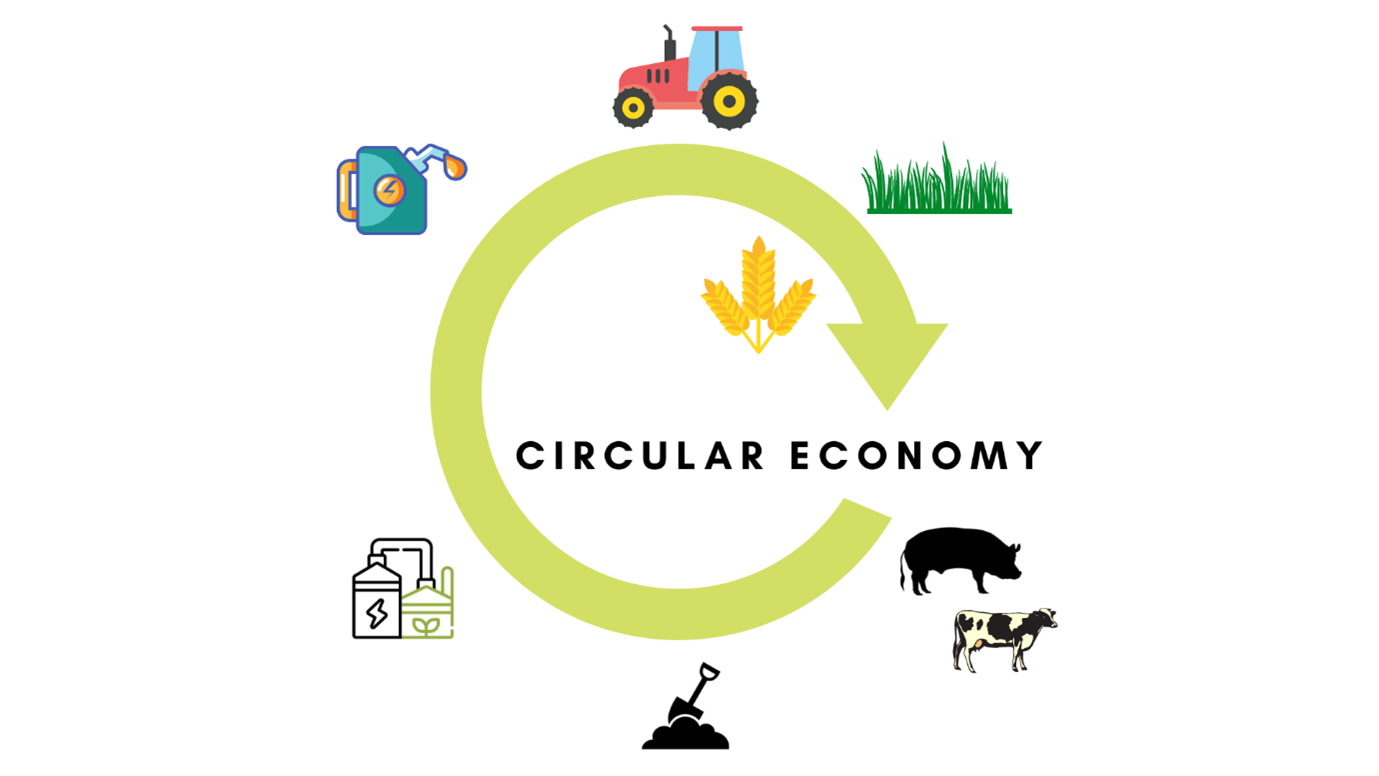

A more recent development in the use of biomethane is as a fuel source for tractors. There are commercially available tractors that run on a variety of fuels, including biomethane. These alternative fuel systems enable the production of feed with a lower carbon footprint as a part of a circular economy.

Anaerobic digestion vs micro AD

The principal processes of AD and micro AD are the same:

- Feedstock goes in

- Bacteria ferment the feedstock to produce methane

- The remaining organic material (digestate) is spread on agricultural land

The main differences are scale (in terms of both size and inputs and outputs), feedstocks and the technology itself. Another key difference is the price in terms of the initial investment. Micro AD plants require a lower initial investment but have a lower output.

Micro AD systems do not require planning permission but are subject to regulations detailed by the Environment Agency.

In both cases, the advantages and disadvantages depend on the resources you have available in terms of space, feedstock, electrical infrastructure and capital to invest. The aim should be to look at what you want to achieve. For those simply looking to decarbonise their production and provide some ROI through the process, micro AD can offer the solution.

For those looking at a fully diversified farm business, full-scale AD may offer a more appropriate long-term investment.

Regardless of which option is chosen, it is important to consider your ability to make use of the digestate. This nutrient-rich material can offset inorganic bagged fertilisers but does require additional interventions:

- Regular testing of the digestate

- Regular testing of the soil nutrients between cropping and applications

- A careful balancing of crop nutrient requirements, as informed by an agronomist and/or based on recognised guidance such as RB209

Case study: slurry scraper and micro AD for pigs

As part of the EUPiG project, a Belgian pig farmer produced a case study explaining their manure management system, from slurry pit design to micro AD.

The original aim of the system was not to generate biomethane but to reduce ammonia emissions from the pig buildings. The producer installed a slanted slurry pit floor allowing urine to drain away from the solid manure. This separation of solids and liquids reduces the ability of bacteria to release ammonia.

He uses a modified dairy scraper to remove the solid manure from under the pig house to use in a micro AD plant.

System costs

- 11% increase in labour costs due to the system maintenance

- An initial cost of €270,000 for the mono-digester

Benefits of the system

- Finishing daily weight gain increased by 5%

- Finishing feed conversion ratio (FCR) improved by 5%

- Veterinary costs per slaughter pig reduced by 30%

- Saving of €40,000/year in electricity costs which means that the investment in the mono-digester will be paid back in seven years

- Improved air quality inside the buildings

Points to consider

- The separated urine could be sold as a specific kind of fertiliser (low phosphorus or high nitrogen) which could further improve the efficiency of the farm or could be a source of ammonia for hydrogen electrolysis

- The manure scraper requires maintenance every two weeks and the mono-digester needs daily monitoring. This contributes to the increase in labour. However, this can be offset by lower fuel costs and income from any FIT received from the sale of electricity to the grid

- By-products are subject to EU waste exemptions and permitting requirements

Read the full case study and access supporting resources

Suppliers directory

|

Supplier |

Website |

Contact details |

|

Biolectric |

Biolectric Anaerobic Digesters generate energy from slurry Dairy Energy |

Email: info@dairyenergy.co.uk Tel: 0781 220 5588 |

|

Bioplex |

Via website only |

|

|

Consentis |

Tel: +49 5925 99860 |

|

|

ERigène |

Via website only |

|

|

HoSt |

Email: info@host-bioenergy.co.uk Tel: 07940 709412 |

|

|

NovaTech |

Email: info@novatechgmbh.com Tel: +49 790 49430 |

|

|

Sauter Biogas |

Tel: +49 351 6587740 |

|

|

SEaB Energy |

Email: sales@seabenergy.com Tel: 020 3003 5086 |

Topics:

Sectors:

Tags: